SeHAWK® FGD System

- is the minimum order quantity for this product. Please check quantity and add to cart again.

Built mainly for compliance for flue gas desulfurization applications in the power industry. It provides consistent performance under the toughest conditions.

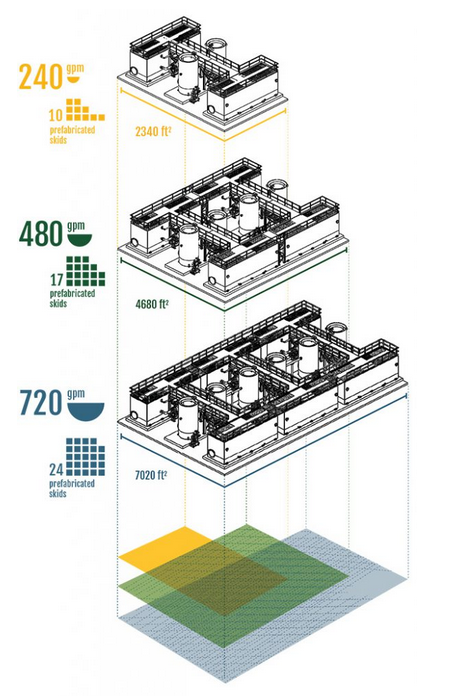

The SeHAWK® FGD is engineered specifically to meet the stringent EPA steam electric effluent limitation guidelines (ELGs) for selenium, nitrate, and metals. Prefabricated, modular bioreactors are integrated with ultrafiltration and scaled to fit a wide range of flows and water qualities. The SeHAWK® FGD equipment is designed for both indoor and outdoor installation and is resilient to changes in feed water temperature and chemistry. All wetted equipment and tanks feature non-metallic construction for superior resistance to corrosion.

|

Flow Range |

100 – 1600gpm |

|

Number of parallel SeHAWK® Trains |

1 – 12 |

|

TDS Tolerance |

40,000 mg/L |

|

Chloride Tolerance |

17,000 mg/L |

|

Selenium Removal Efficiency |

≥95% |

|

Equipment Delivery Timeline |

<18 Months |