How to Harness the Power of Your Condition Data

Collecting condition data is critical for proactive pipeline management. Being able to make effective decisions on that data is just as important. Learn how advanced structural analysis helps utilities get more out of their inspection data.

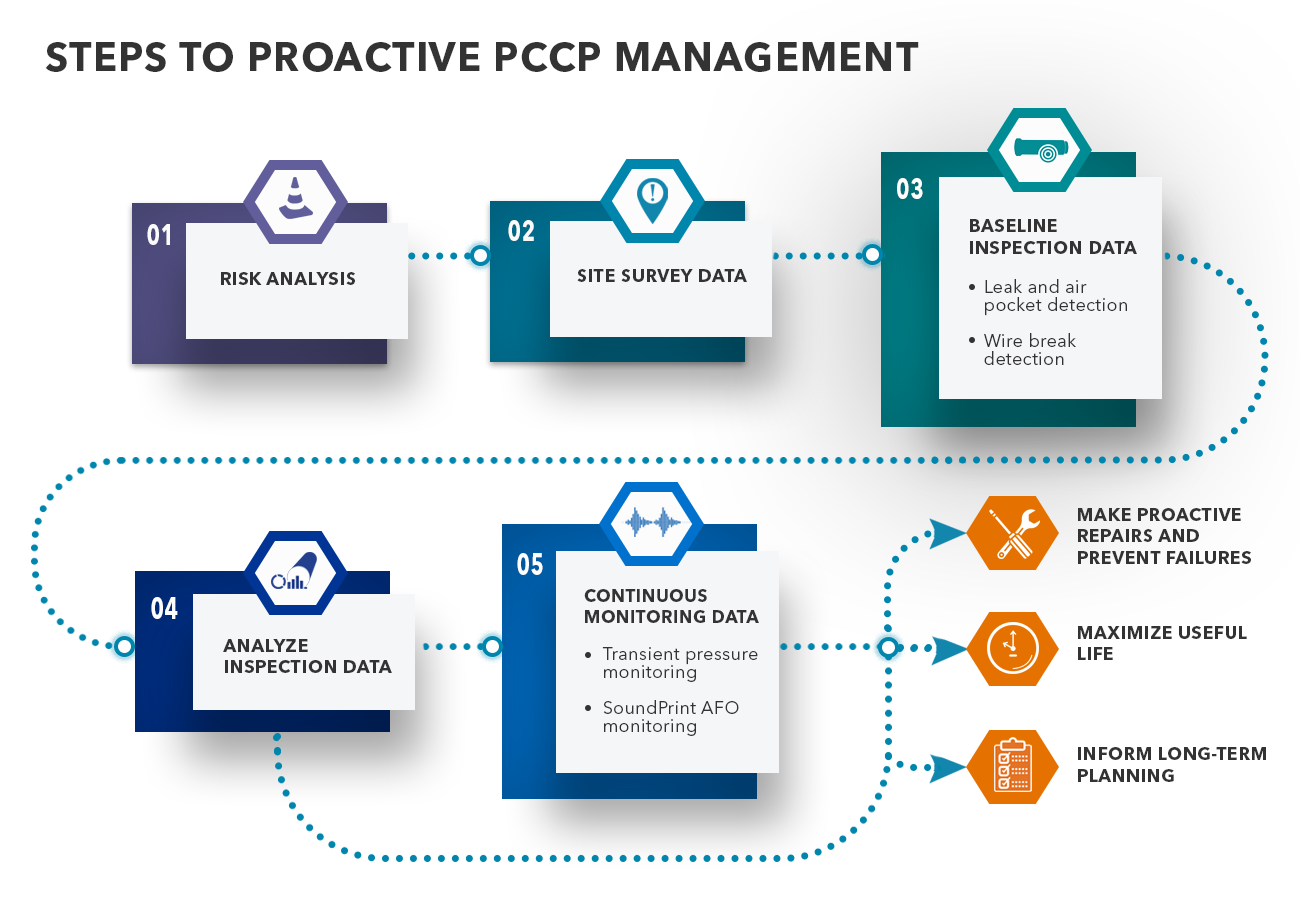

Prestressed concrete cylinder pipe (PCCP) is a dependable pipe material common in large-diameter water mains and force mains. Although rare, PCCP failures tend to be catastrophic and come at a high cost to the community. Fortunately, utilities can harness the power of condition data to make informed decisions and ensure safe pipeline operation.

Understanding Risk

Utilities often perform a desktop risk analysis to determine the likelihood and consequence of pipeline failure. Utilities use risk analysis to inform management actions and capital investments.

However, because transmission main failures are rare, it is difficult to identify specific assets that are likely to fail.

Pipe attributes, such as age and material, don’t correlate well with the probability that a transmission main will fail. This means traditional desktop analyses cannot reliably predict which pipes are deteriorating or nearing failure.

When transmission mains do fail, the social, environmental, and economic consequences can be very high. Understanding consequence of failure helps utilities choose from an array of available condition assessment techniques and technologies.

For instance, low consequence pipelines may warrant cheaper screening tools that identify red flags but provide a limited understanding of pipe condition. A highly critical transmission main, however, warrants a detailed quantification of pipe wall integrity.

PCCP failures can be particularly catastrophic, as this material is used primarily in critical, large-diameter pipelines. PCCP pipelines typically have the highest consequence of failure in a transmission network. As a result, PCCP pipelines call for a high-resolution assessment approach that yields precise probability of failure and accurately forecasts future asset condition.

Gathering PCCP Condition Data

Today, non-destructive electromagnetic inspection is the most common method of assessing PCCP pipelines. Electromagnetic technology can determine the condition of each pipe’s prestressing wires. Steel prestressing wire is the primary structural component of PCCP. Understanding the condition of the wire is critical, and quantifying broken wire wraps provides the best indicator of potential failure.

Historically, inspecting PCCP required utilities to dewater their pipeline and conduct a manned visual and sounding inspection. While visual inspections can provide valuable data, they are not always feasible and have shortcomings. Technicians can’t quantify broken wire wraps or identify low to moderate levels of distress when there is no visual evidence of pipe wall damage. To solve this problem, piloted electromagnetic inspection carts were developed. These carts are pushed through the pipeline during a visual inspection.

Today, there are far more options for collecting electromagnetic data that can accommodate a utility’s operational constraints. Inline, free-swimming tools operate while the pipeline remains in service. Robotic inspection tools are available for pipelines that can be depressurized but not necessarily dewatered. These tools can also access pipelines that are too small or unsuitable for manned entry.

These inspection options provide PCCP owners with an easier, safer, and less costly alternative to inspection methods that require shutdown and dewatering.

Transient pressure monitoring also adds value by identifying pipeline operating and surge pressures. This information helps utilities address dangerous operating conditions and provides critical information for further structural evaluation.

Making PCCP Condition Data Actionable

A pipe with broken wire wraps does not necessarily require immediate repair. Interpreting electromagnetic inspection data provides an understanding of how much damage is “too much” and when action is warranted. Advanced structural analyses can reveal the significance of inspection data and help guide decisions about when to reinspect, repair, or replace PCCP.

Finite element analysis (FEA) modeling can give an accurate representation of pipe condition using inspection data. These structural models can predict how pipes with wire break damage respond to known loading conditions.

The result is a pipe performance curve that shows when a pipe is expected to reach its yield limit. This is the limit at which a utility should consider prioritizing pipe rehabilitation based on the number of wire breaks and operating pressure. FEA helps utilities determine which pipes need to be replaced immediately and which can be prioritized for future repair or reinspection.

Mitigating Risk and Making Better Decisions

Utilities can avoid failures by making selective, proactive repairs. There are several common repair methods for PCCP, including:

- Pipe replacement

- Carbon fiber reinforced polymer repair

- External post tensioning tendon repair

- Sliplining

Also, where possible, operational changes to reduce pressures (operating or transient) can reduce the risk of failure and prolong the life of damaged pipes.

The right mitigation approach depends on a number of factors beyond pipe condition, such as risk tolerance, cost, life expectancy of the repair, downtime and impact to customers, and pipe attributes, to name a few.

The completed condition assessment is a snapshot in time. Regular reinspection identifies new areas of distress and determines whether existing problem areas are worsening.

Utilities may also consider monitoring the pipeline to track PCCP deterioration over time. Xylem’s SoundPrint® AFO monitoring platform provides continuous, near-real-time wire break data. This early warning system alerts utilities to a potential failure with time to make planned repairs.

Condition assessment is key to making effective asset management decisions. Structural analyses maximize the usefulness of PCCP inspection data by transforming it into actionable information. With the strategies discussed in this blog, utilities can make informed risk mitigation decisions and prevent near-term pipeline failures.

Utilities can also use condition data to forecast future pipe states, providing a data-driven reinspection interval and capital planning guidance. Stay tuned for the next blog in our series, which will cover long-term pipeline management strategies.

Learn more about how you can leverage your PCCP condition data.