Flygt Premium efficiency motors meet IE3 efficiency requirements in IEC standards as well as the Premium efficiency requirements in the NEMA standard. Flygt specifically designs the motors to fit our submersible pumps and makes them available in sizes from 2 kW to 230 kW. The design aims to reach the highest possible motor efficiency with the losses centered around the stator in order to utilize the available cooling in the best possible way. This results in a very long motor and bearing life and a cool running machine.

The Premium efficiency motor range consists of two motor technologies. For the larger sizes we use the conventional induction motor technology, and for the smaller motors we've designed Line Started Permanent Magnet motors (LSPM technology).

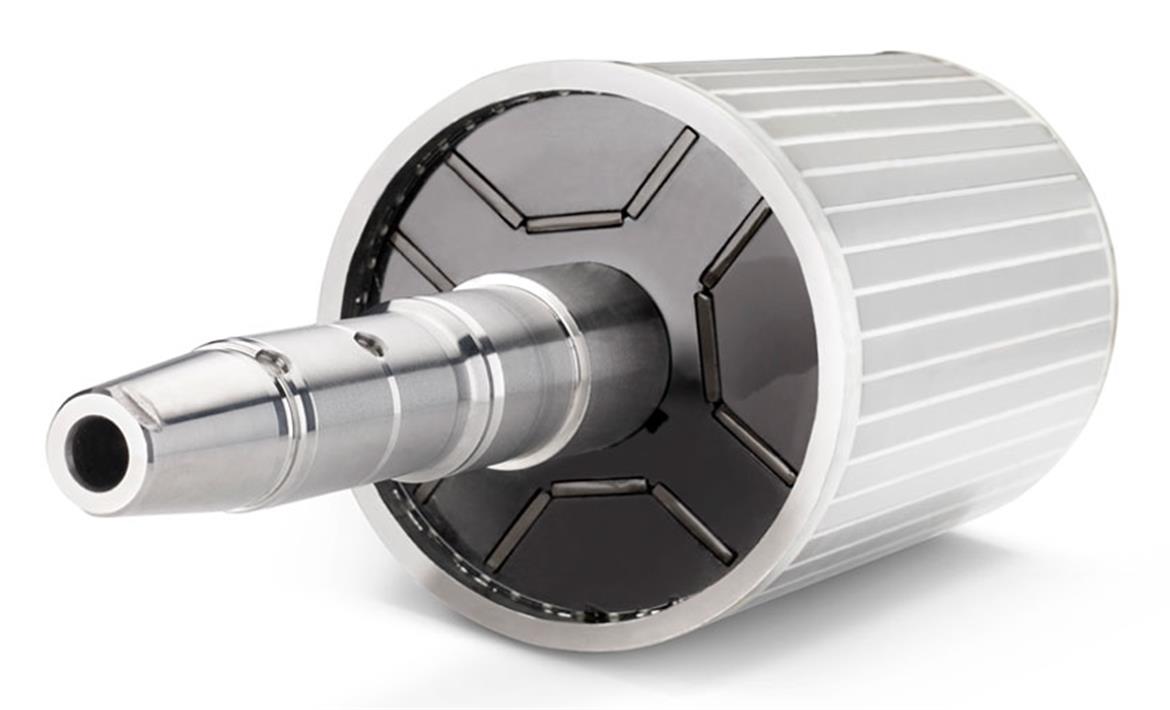

The innovative Line Started Permanent Magnet motors up to 12.5 kW

Flygt first introduced the world’s first commercially available LSPM motors in our mixers in 2009. After many years of prior R&D experience, we brought these state-of-the-art motor designs to market. We've developed LSPM technology motors up to 12.5 kW that are both powerful and extremely efficient. This technology delivers up to 4% higher efficiency than the nominal value of the International Premium efficiency standard (IEC 60034-30-1) set by European regulations and the NEMA MG-1 standard.

Flygt LSPM motors are designed to draw less current, which allows for smaller cables and less expensive protective devices. This makes it simple to retrofit an old pump and keep your existing control panel. You can start the flexible LSPM motors using all common starting methods. All our engineering efforts focus on ensuring we have motors that are as slim and light as possible.

For motors 12.5 kW and larger, we utilize conventional motor technologies to achieve the premium efficiency levels. Some motors larger than 70 kW are fitted with full copper bar rotors and special high-efficiency windings and stator/rotor laminations.

Benefits of Premium efficiency motors:

- Highest submersible motor efficiencies on the market

- International Premium efficiency standard

- Lower motor temperatures prolongs motor and bearing life span

- Optimized for pumps and pump applications

- All common starting methods possible