EPAL cuts real water loss by 1.7 million cubic meters annually using high-precision pipeline inspection technologies

EPAL

Lisbon, Portugal

Founded in 1868, EPAL is the oldest and largest bulk water company in Portugal, supplying services to 35 municipalities throughout the county. In Lisbon, EPAL serves a population of more than 500,000 with 167,000 m3 of water delivered daily through a distribution network that includes more than 1,400 kilometers of pipe.

Over the last 15 years, EPAL has successfully deployed a network monitoring project aimed at reducing Lisbon’s water losses.

The mainstay has been the implementation of more than 160 District Metered Areas (DMAs), along with associated flow and pressure monitoring equipment and telemetry systems, undertaken in tandem with EPAL’s ongoing renewal and rehabilitation program.

The DMA project has been a huge success. Between 2005 and 2014, EPAL reduced their real water losses from 23 percent to 8 percent, corresponding to a reduction in water loss from nearly 27 million m3 a year to just over 8 million m3 per year.

Challenge

In 2016, EPAL recognized a deviation in the non-revenue water (NRW) trend since implementation of the DMA program. The issue was promptly identified in two supply zones, encompassing 150 kilometers of water transmission mains, predominately composed of large diameter reinforced concrete pipe built in 1965.

Detecting leaks in large-diameter transmission mains is challenging using conventional methods. This is often due to complexity of the system, the (expected) inaccuracy of bulk flow meters to detect very small flow variations and the limitations of traditional leak detection methods such as correlation and field hydrophones. As a result, EPAL was open to investing in specialized leak detection technologies to identify the source of leaks.

“We were impressed with the accuracy of SmartBall and Sahara tools at identifying the precise locations of leaks on the trunk mains, inspected while the lines remained in service.”

Andrew Donnelly, Water Loss Control Coordinator, EPAL

Solution

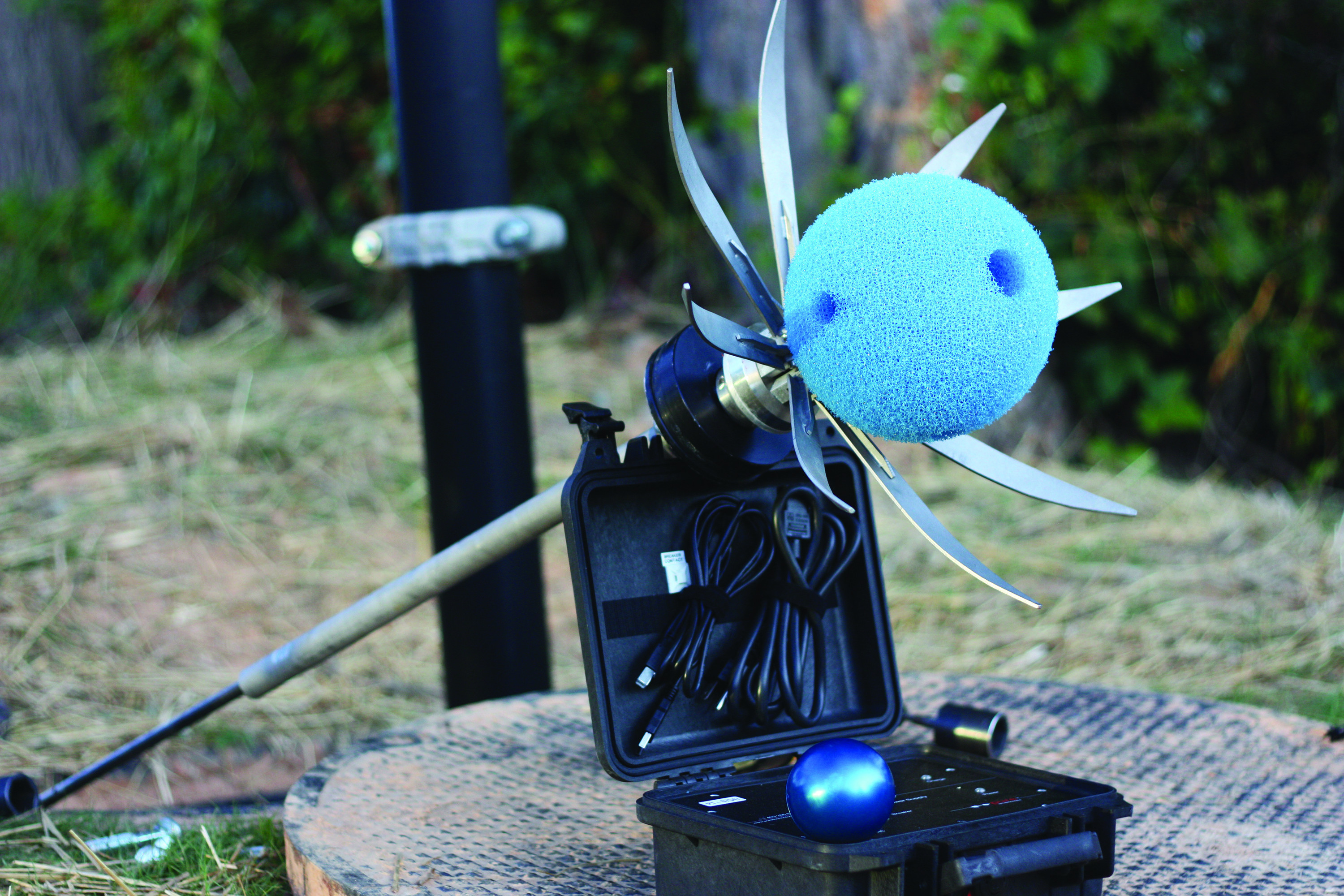

In 2017, EPAL partnered with Xylem to address this real water loss. Xylem recommended two highly reliable and precise inline acoustic technologies–the tethered Sahara™ for shorter runs and the free-swimming SmartBall™ for a longer survey.

TheSahara utilizes a variety of sensor tools to perform the inspection, including an acoustic sensor that performs leak and air pocket detection, and high-resolution video camera to assess internal pipe conditions. The Sahara tool is drawn by water flow via a small drag chute and is tethered to a data acquisition unit on the surface, giving the operator close control to confirm suspected leaks, air pockets, and other visual anomalies.

For a longer survey,SmartBall was deployed. The tool rolls along the bottom of the pipe with the flow of water, identifying leaks and gas pockets while the line remains in service, minimizing disruption. The SmartBall is designed to navigate bends and travel many kilometers under a single deployment, making it the appropriate the choice for the longer inspection.

Outcome

The Sahara was used in multiple inspections and identified 26 leaks on 10.5 kilometers of pipeline while the SmartBall was used in a single inspection and identified 11 leaks on 1.6 kilometers of pipeline.

After conducting more than 8000 kilometers of inspections worldwide using these technologies, Xylem typically finds an average of three leaks per 10 kilometers for these types of pipes. In EPAL’s case, a much greater number of leaks was identified. The reason for such a high leak rate likely lies in the precision of the preliminary study (developed by EPAL in-house) to support the choice of pipes inspected. Based on their experience and existing system information, EPAL focused their SmartBall and Sahara inline leak detection efforts precisely on those areas that were known “blind spots” for traditional leak detection methods.

Since the inspections, EPAL has been proactive in repairing the identified leaks. The results speak to the precision of the SmartBall and Sahara tools: In the two key supply zones, EPAL has reduced NRW by 17 percent and 36 percent, representing a NRW reduction of approximately 1.7 million m3 annually.