Biogas - environmental and sustainable energy production

The utilization of substrates offers a high energy potential, whether it is manure, silage, food processing waste or even food leftovers from restaurants or private households. Biogas production transforms these waste streams into energy while reducing greenhouse gas emissions. In this process, energy that is not used in the company's own operations can be profitably sold to the public grid. Anaerobic digestion is a natural process based on a simple concept. However, efficient biogas production requires that mostly difficult substrates can be pumped and mixed effectively.

Energy generation from waste: Xylem increases the safety of your processes and ensures optimal efficiency

- To ensure homogeneity, the substrates are kept in motion.

- The mixing of the substrates prevents materials from floating and settling.

- The substrates are a combination of low-density fibrous media and heavy materials.

- The goal of the pumps is to provide a consistent feed without clogging

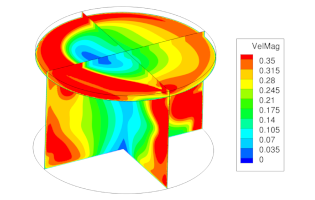

Go for an optimal ratio between thrust and power

There is more to the efficient mixing process than the ratio between power consumption (in hp or kW) and volume. The efficiency of a mixing operation also depends on how much thrust is generated per unit of energy (N/kW). Xylem's comprehensive line of mixers, with excellent thrust-to-output ratios, can be used for installation in a variety of tank configurations and substrate mixes. For best mixing results, place mixers to ensure optimum mass flow. Mixer installation depth and angle should be adapted to the tank configurations and substrate characteristics. Fully submersible mixers with depth and angle adjustment allow the most flexible configurations and highest energy efficiency.

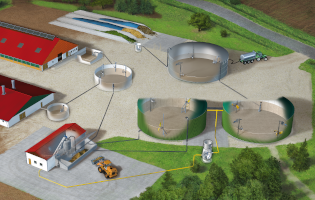

Feeding tank / Preparation tank

• Blending substrates into a homogeneous feedstock

• Blending substrates into a homogeneous feedstock

• Distributing solids evenly

Recommended products: Flygt Single Speed Mixers

Digester

• Providing of a homogeneous substrate as feedstock for biogas-generating bacteria.

• Providing of a homogeneous substrate as feedstock for biogas-generating bacteria.

• Preventing crust and foam formation

• Maintaining a stable and optimal temperature throughout the digester tank

• Mixing of the entire tank contents

• Releasing biogas bubbles at all depths of the digester to bring them to the surface for extraction

• Preventing sedimentation

Recommended products: Flygt Single Speed Mixers

Storage tank

• Providing of a homogeneous mixture of the fermented substrate for field applications.

• Providing of a homogeneous mixture of the fermented substrate for field applications.

• Re-suspending of the settled solids before pumping

Each tank and each process requires a perfectly tuned mixing system to keep the substrates moving, and maximize energy production.

Recommended products: Flygt Single Speed Mixers

Your requirement and our matching combination of suitable mixers

Your mixer requirements will depend on your substrates, your tank geometries, and your throughput. To ensure uniform mixing throughout the digester, a good understanding of the density gradients of the various substrates used in digesters as food for the bacteria is needed.

Your mixer requirements will depend on your substrates, your tank geometries, and your throughput. To ensure uniform mixing throughout the digester, a good understanding of the density gradients of the various substrates used in digesters as food for the bacteria is needed.

Recommended products: Flygt 4460 Biogas Mixer, Flygt Single Speed Mixers, BIS-1 Biogas Support System, SI Analytics TitroLine® 5000 Autotitrator, Flygt N-Technology Pumps, Flygt Chopper Pumps, Flygt Vortex Pumps

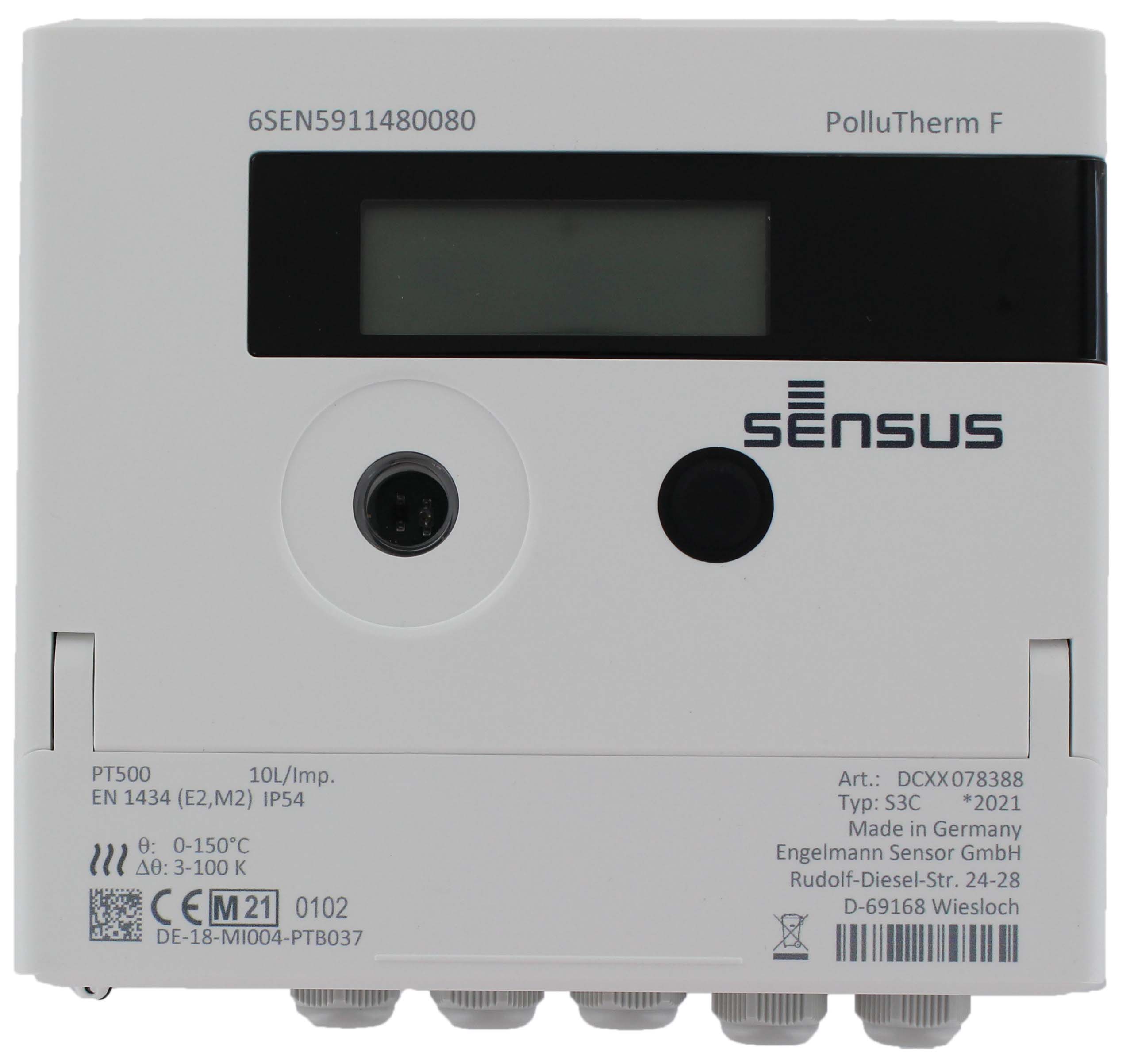

Thermal Energy Meters

The main product of biogas plants is power, and the main challenge for power generation is the sustainable use of the waste heat. The use of waste heat from Combined Heat and Power (CHP) units is a crucial factor for the economic and environmental performance of biogas plants. Thermal energy meters measure accurately the heat or cooling energy to be used for District Heating/Cooling coming from the CHP unit.

The main product of biogas plants is power, and the main challenge for power generation is the sustainable use of the waste heat. The use of waste heat from Combined Heat and Power (CHP) units is a crucial factor for the economic and environmental performance of biogas plants. Thermal energy meters measure accurately the heat or cooling energy to be used for District Heating/Cooling coming from the CHP unit.

Recommended Products: PolluWatt™ Duo II with mechanical flow sensor 90 °C/PN16, PolluTherm® F with PolluFlow with ultrasonic flow sensor 90 °C/PN16, PolluTherm® with PolluFlow with ultrasonic flow sensor 130°C/PN25, PolluFlow ultrasonic flow sensor 90 °C/PN16 or 130°C/PN25