What Hydrogen Means for the Gas Industry, Part I

Energy fundamentals and hydrogen applications

This is the first post in the series, Hydrogen and Its Potential for the Gas Industry, on the Sensus blog. This series will review the fundamentals of hydrogen as well as the impact and opportunity it holds for natural gas utilities and their end customers.

________________________________

Hydrogen is the most abundant element in the universe. Just look up on a clear day and you will see a perfect example in the sky. The sun, as with most stars, is a giant ball of hydrogen and helium. However, for such an abundant element, pure hydrogen is hard to come by on earth since it only exists in compound form with other elements (Hydrogen Explained – U.S. Energy Information Administration (EIA), n.d.). In chemistry and biology classes they teach that hydrogen is one of the six main elements that are core to life, with the others being sulfur, phosphorous, oxygen, nitrogen, and carbon. (2: The Chemical Building Blocks of Life – Medicine LibreTexts, n.d.). So how can this element, one of the main building blocks of life, help to transition countries to a cleaner energy future? To begin to answer that question, this blog post will introduce the fundamentals of hydrogen and how it is currently used in industry. This is the first post of a blog series and the other blog posts in the series will expand on the topics covered here to discuss in depth how hydrogen will play a role in the world’s energy transition.

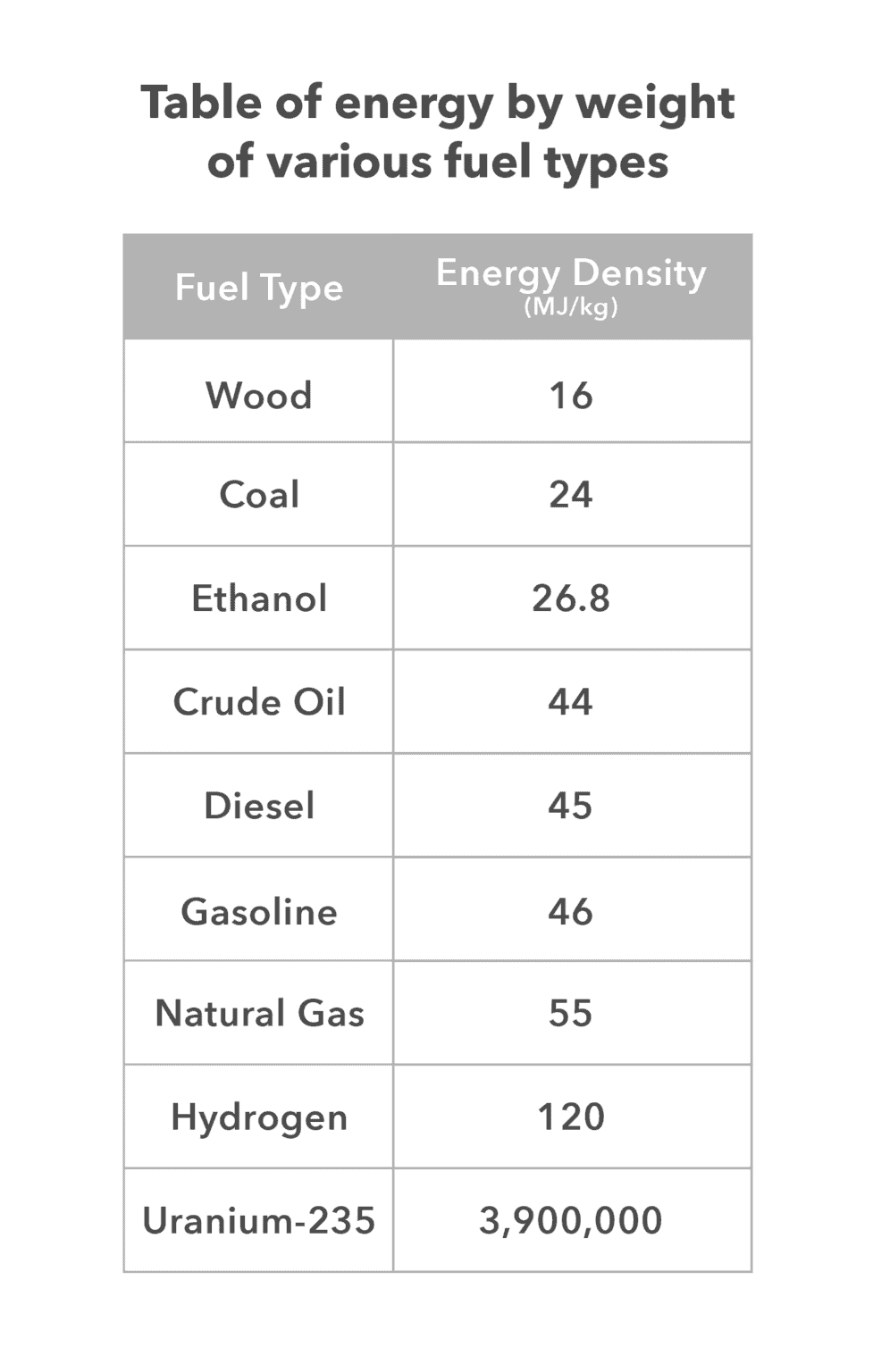

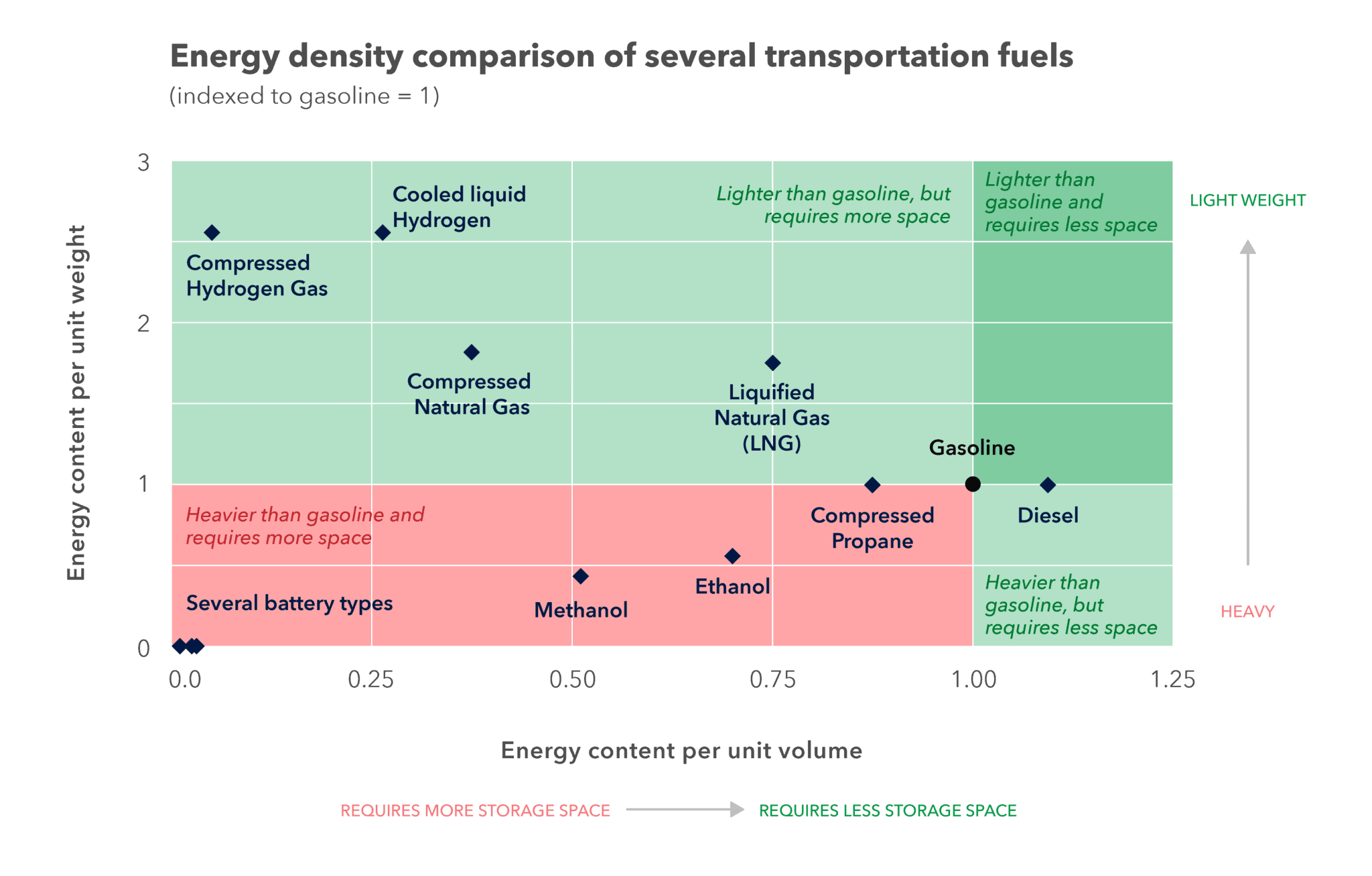

Energy Fundamentals

Energy sources are evaluated based on their energy per unit volume and energy per unit mass. Hydrogen has three times the energy by weight of gasoline, or 1 kilogram of hydrogen gas has about the same energy as 1 gallon of gas, 2.8 kilograms (Alternative Fuels Data Center: Hydrogen Basics, n.d.). However, hydrogen has low energy content by volume, about 1/6th of the energy by volume of a gallon of gasoline. This low energy by volume is one of the main barriers for adoption of hydrogen in the energy industry.

Energy Carrier vs Energy Source

When discussing hydrogen and energy, it is important to note that hydrogen is an energy carrier and not an energy source.

- Energy sources, sometimes called primary energy, are forms of energy that are found in the natural environment. They are typically categorized into one of two groups – the finite, which include nuclear and fossil fuels, and the renewable, which include solar, wind, and water (Rosen, n.d.).

- Energy carriers are the energy forms in which energy is transported and used. One example of an energy carrier is electricity. Electricity does not exist, at least in a usable form, in the natural environment, but carries energy from a source to an end-use application.

Some energy sources are also energy carriers, such as most fossil fuels, since they are transported and used in approximately the same form that they are found in the environment. Other energy sources, such as solar, cannot be transported in their natural form and need to be converted to energy carriers in order to be used. Hydrogen is similar to electricity in that it is only an energy carrier, and can be used to transfer energy from source to end use.

End Use

Currently, demand for hydrogen is dominated by two main markets: refining and ammonia production. But, the demand for hydrogen is growing, with overall demand expected to almost double by 2030 (Hydrogen – Analysis – IEA, n.d.).

One area leading this growth in demand is grid injection, which is where hydrogen would be injected into the existing natural gas grid. It would then be used in applications where natural gas has traditionally been used, such as for heating homes or in gas range ovens.

Another area with high investment is hydrogen fuel cells for transportation. While many experts see electric vehicles as the pathway to a clean automotive future, some see fuel-cells as a better alternative for heavy load or long-range applications such as long-haul trucking.

As the capacity for renewable energy sources increases, there is a growing need for energy storage, and hydrogen can help fill that void. The idea is similar to storing excess electricity in batteries – hydrogen can be created with excess electricity and then stored in salt caverns, storage tanks, or fuel cells. There is specific interest in low-carbon hydrogen, often called green hydrogen, which is hydrogen that is produced through means that release no or low carbon to the atmosphere.

Production

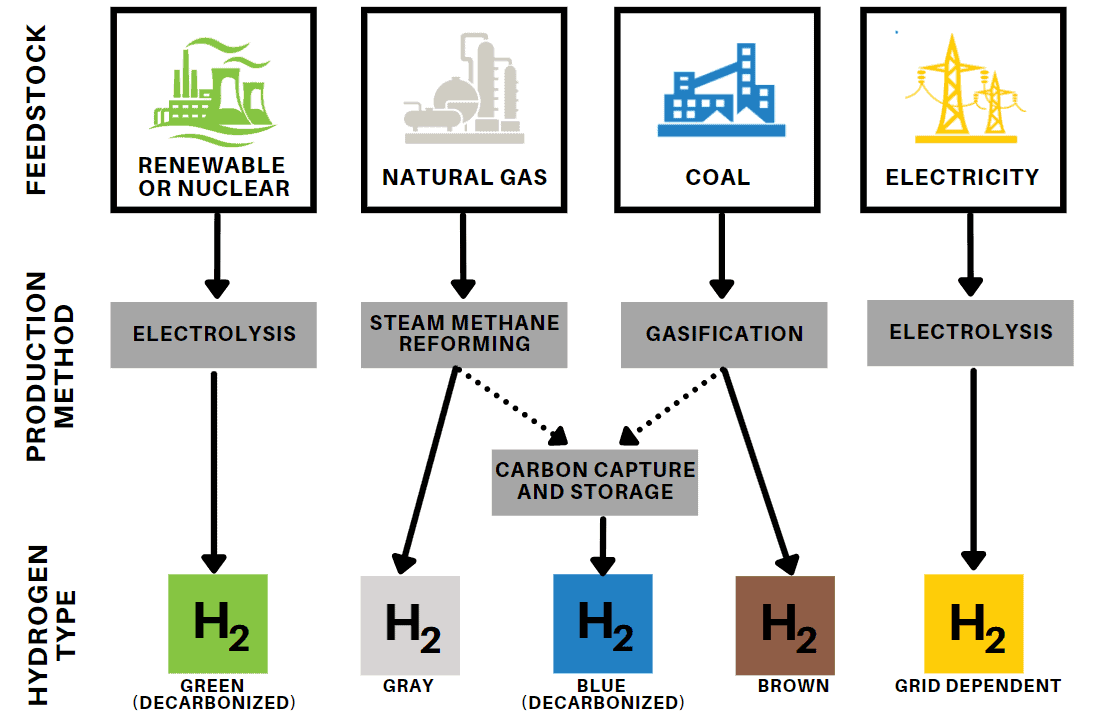

To get hydrogen in its pure form, it needs to be separated from a compound where it exists naturally on earth. This can be done using one of three main methods and feedstocks:

- Fossil fuels through steam methane reforming or coal gasification

- Biomass and waste

- Water through electrolysis

The feedstock for hydrogen production determines the carbon intensity of the hydrogen produced. A color-coding scheme with 9 colors was developed to rank the hydrogen production methods by carbon intensity (Hydrogen Colours Codes – H2 Bulletin, n.d.). However, the three most important colors are described in the diagram below.

Green hydrogen is produced using renewable energy and water in a process called electrolysis, which uses electricity to split water into hydrogen and oxygen. If renewable energy is not used to produce the electricity in the process, then the hydrogen is not considered green and the carbon intensity of the produced hydrogen depends on the carbon intensity of the local electricity used.

Steam methane reforming produces what is classified as gray hydrogen and is the dominant form of hydrogen production due to cost. Steam methane reforming uses steam, natural gas, and a catalyst to produce hydrogen and carbon monoxide.

Coal gasification uses coal as a feedstock to produce brown hydrogen and is common in areas where the cost of coal is cheap. Heat and pressure are used in this process to break coal into its chemical constituents.

The hydrogen is classified as blue when a fossil fuel feedstock production method, such as steam methane reforming, is combined with carbon capture, utilization, and storage (CCUS).

There is an effort in the energy industry to quantify the carbon intensity of each production method and move away from the color code. Quantifying the carbon intensity of the production method of hydrogen will help hydrogen users choose the lowest-emission hydrogen source in cases where green hydrogen is not available. A future blog post will dive into how carbon intensity, associated cost, and how the different production methods will play a role in the future of hydrogen.

Transport

Once hydrogen is produced, it needs to be transported to its end source before it can be used. Hydrogen is transported using pipelines or by road in liquid tanker trucks or gaseous tube trailers (Hydrogen Delivery | Department of Energy, n.d.). Liquid tankers transport hydrogen gas that has been liquefied by cooling it to below -253⁰C (-423⁰F) in super-insulated cryogenic tanker trucks (Liquid Hydrogen Delivery | Department of Energy, n.d.). At the end-use site, that liquified gas has to be vaporized to a high-pressure gaseous product for use. Gaseous tube trailers transport hydrogen as a gas, which is less efficient in terms of volume transport, but does not require energy to liquefy and revaporize. Hydrogen is not currently widely transported by rail in the US.

Conclusion

Hydrogen is a low-carbon energy carrier that will help many sectors transition to low and zero-carbon fuels. Specifically, it can help utilities achieve their net-zero and emission reduction goals. Future blog posts in this series will explore hydrogen compatibility of the current and future state energy network, energy regulation and resources, the technical feasibility of using hydrogen as a fuel source, and other topics.