How do I choose the right pipeline inspection tool?

There is no one-size-fits-all approach to inspecting critical pipelines. Utilities should carefully compare technologies to determine how they meet your operational and project delivery needs as well as your decision-making goals. Here are four key considerations utilities should evaluate when choosing the right tool for a condition assessment project.

1. Safety

All pipeline inspections involve risk, but some approaches are safer than others. Inspection tools that are partially or fully autonomous can reduce the risk of injury by decreasing time spent in the right of way, in open trenches, or confined spaces.

See how Urban Utilities adopted a new inspection approach that eliminated long hours inside a pipeline, decreased truck rolls, and reduced disruption to utility operations and sensitive local landscapes.Read the article.

2. Ease of Operation

The level of effort required to prepare the pipeline for inspection as well as disruption to normal operations during the inspection are also important considerations.

Most water transmission mains and wastewater force mains were not designed to be inspected, making tool access and passage difficult. Some tools require extensive civil work or other preparation before the inspection, such as exercising or even removing valves, installing custom fittings to insert and extract the tool, or using a gauging pig to confirm pipeline geometry. These efforts can quickly add to the cost of an assessment.

Some critical pipelines cannot be shut down, or shut down windows are extremely limited. Human entry into the pipeline requires dewatering, double isolation, and rope support for steep slopes. Inline, free-swimming tools can operate while the pipeline remains in service while other tools may require depressurization, dewatering, or excavation (for external tools).

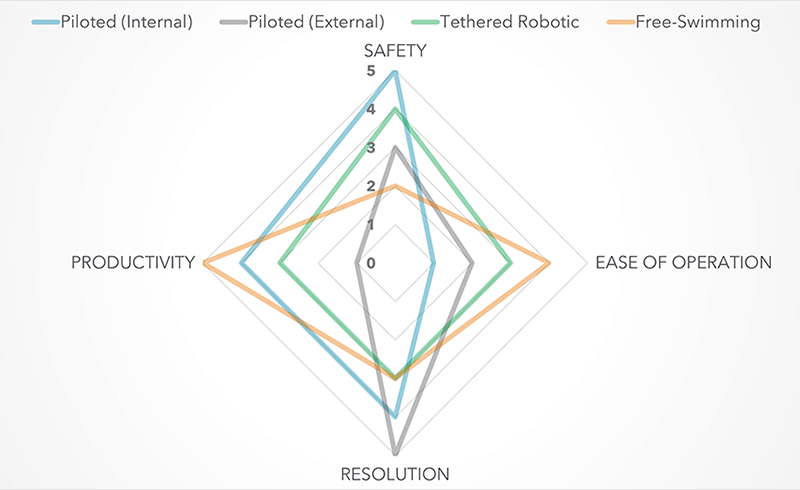

The spider chart above compares four electromagnetic inspection technologies and provides an example of how utilities can evaluate tools using four criteria: safety (lower score is better), ease of operation (higher score is better), productivity (higher score is better), and resolution (higher score is better).

3. Productivity

Productivity refers to the inspection distance a tool can cover in a given amount of time. This parameter is especially important during an emergency or a limited inspection window.

More productive tools are ones that can complete inspections in a single run and pass valves, bends, and tees without having to be removed from the pipeline at these features. Productivity does not have to come at the expense of the other parameters. The right tool improves productivity, making it easier for both utilities and your inspection partner to get the job done.

The Homestake Water Project in Colorado would shut down their pipeline for one month every September. It took five years to inspect 45 miles of pipeline. See how they covered the same inspection distance in one day with the PipeDiver platform.Watch the video.

4. Data Resolution and Coverage

Higher-resolution tools can measure pipeline deterioration in greater detail. However, there is generally a tradeoff between resolution, cost, and effort. It is helpful to consider the level of resolution you need to meet your risk reduction goals and inform your plans for the asset.

In the field, there are many factors that can impact data resolution and coverage — from sediment buildup to flow rate. Real-world tool resolution often varies from what is reported under ideal conditions in a test environment. Validation helps ensure tools meet your performance requirements, informs repairs, and ultimately leads to better inspection outcomes.

It is also useful to be aware of tool blind spots. A phased or multi-tool approach can help compensate for limitations where needed.

Project Management: An Additional Consideration

Though not specific to inspection technologies, project management is another important consideration when selecting a partner. Can your partner meet the required scope on time and on budget? Can they offer additional support, such as complementary inspection tools, data modeling, valve assessment, pipeline tapping, and dewatering?

No matter what tool you choose, a successful inspection starts with open dialogue, planning, and coordination with your assessment partner. Talk to the experts at Xylem to explore potential options. We can help you determine the right fit to meet your operational requirements and exceed your expectations.