When our standard pump station designs are not appropriate for your site conditions, we can help design a customized pump station based on project requirements. Our engineering expertise and vast experience contribute to pump station designs that, together with Flygt pumps and accessories, ensure a reliable and cost-effective project. The designs are made to handle various inflow conditions, minimizing solids build-up and arranging multiple pumping units in order to achieve an efficient, well-designed pump sump.

One of the main design requirements for a sump design is to provide optimal inlet conditions for the pumps. This means that the flow being delivered to the pump inlets is uniform, steady, and without swirl or entrained air. Another critical aspect is to minimize sedimentation and debris in the station. Other factors that can impact operations, such as site conditions, type of media and local regulations and practices, should play a key role in station design.

VERIFYING THE DESIGN

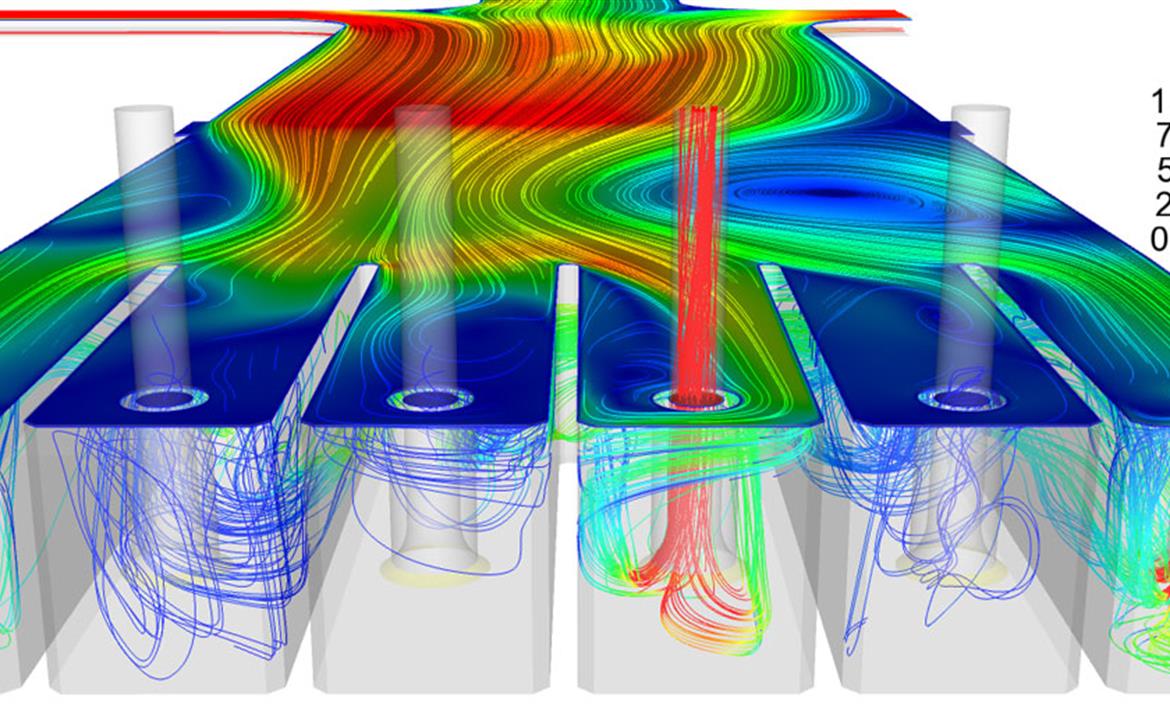

To verify a design when there's little or no prior experience, we use computational fluid dynamics (CFD). It's a mathematical modeling of the proposed pump sump design where flow pattern can be observed under different operating conditions. Flygt pioneered the use of CFD to verify sump design, and we have been using it for over 30 years.

In addition, we use physical scale model tests to identify solutions for existing and proposed installations. This has proven to be a far less expensive way to determine the viability of possible solutions than through trial and error at full scale and as an alternative to a CFD analysis in certain cases.