Low Pressure Steam Heating System Application and Selection Guide for Residential and Commercial Systems

Volume 7/ Issue 1/ January 2020

This article is intended to simplify the selection of components for a steam heating system. The majority of steam boilers used in heating systems are rated on the BTU heat output. Selections are based on modern steam boilers, many older steam boilers had sufficient water storage capacity to fill the heating system with steam and then wait for the condensate to return. Modern steam boilers have much less usable water capacity that can cause boiler flooding or low water conditions to occur.

The tables recommend that a boiler feed unit should be used on all boilers over 300,000 BTU. The boiler feed receiver then becomes the reservoir for the system. The net usable storage capacity of the boiler feed receiver should be between 10 and 20 minutes. The minimum capacity shown in the tables is 10 minutes. Single level buildings that are spread out over a large area should be increased to 15 or 20 minutes.

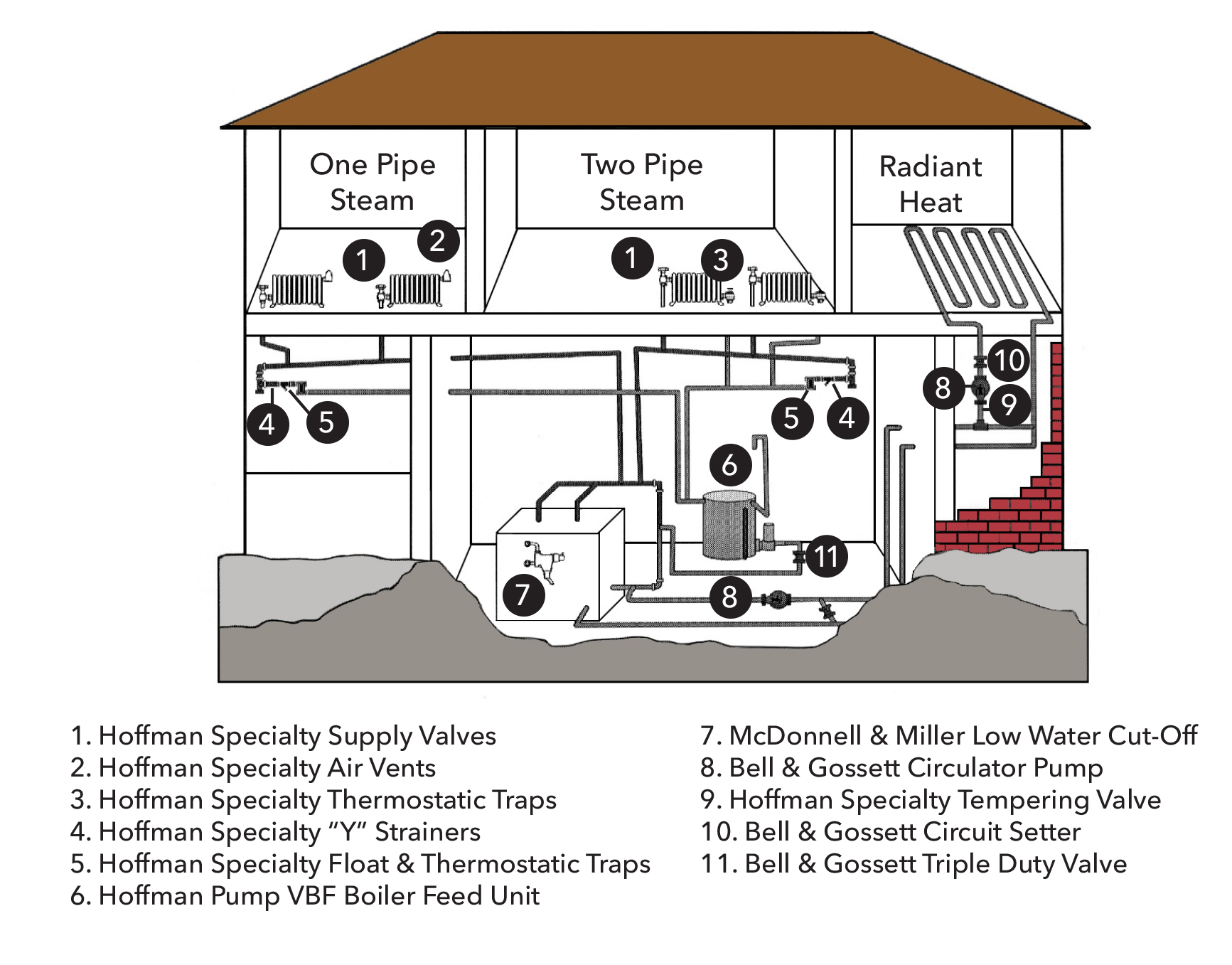

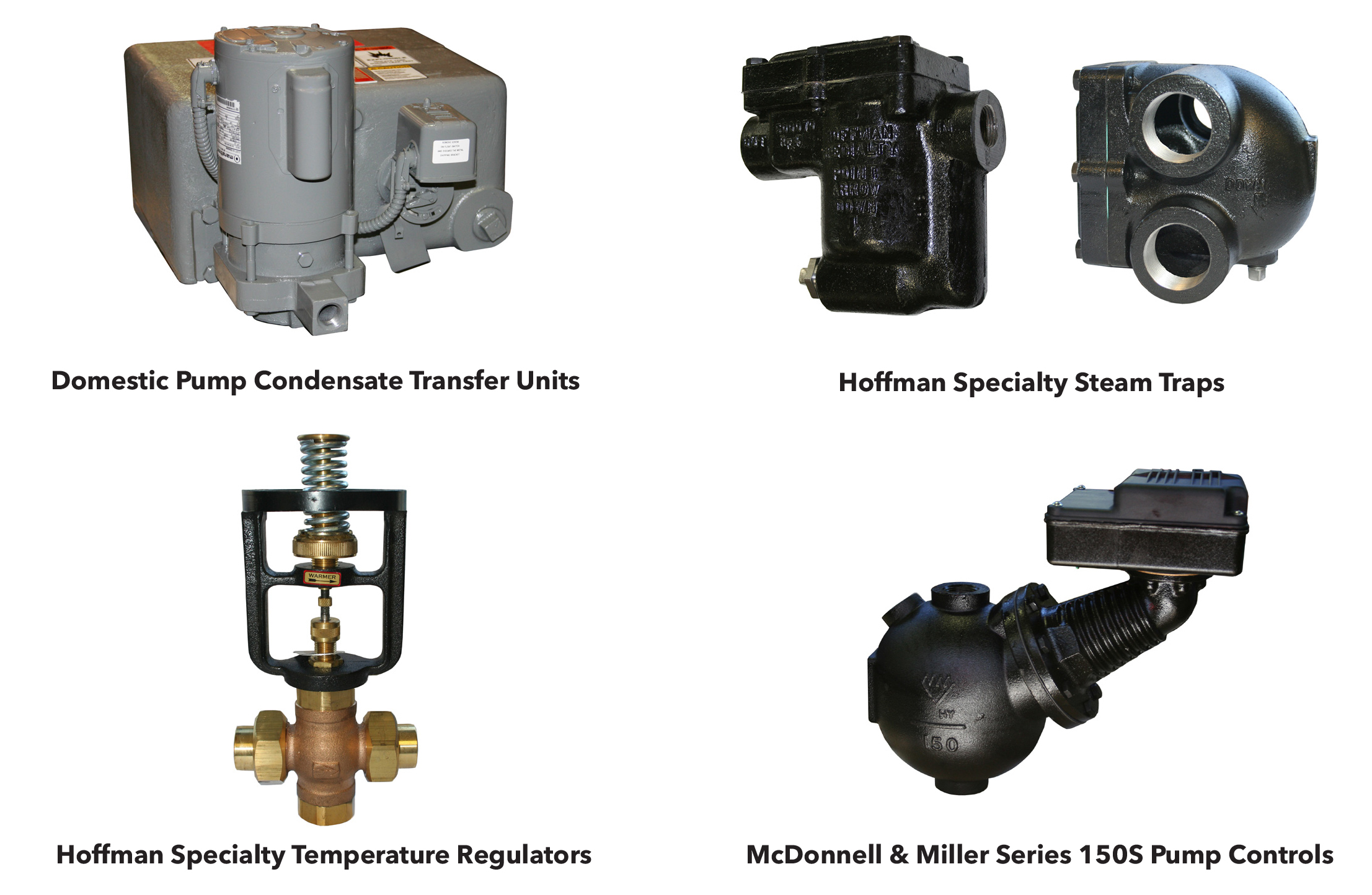

The Xylem “Steam Team” includes a wide range of steam products. When it comes to expanding, upgrading or repairing your steam system it pays to have a partner like Xylem. We make the parts. We build the system, and we know them inside and out.

Our “Steam Team” representatives are experts in steam heating systems and have the answers you need to get the job done right. They’re the only ones that handle a full line of products that include Domestic Pump condensate handling equipment, Hoffman Specialty air vents, supply valves and traps, and McDonnell & Miller boiler controls. Consult your local representative for more information.

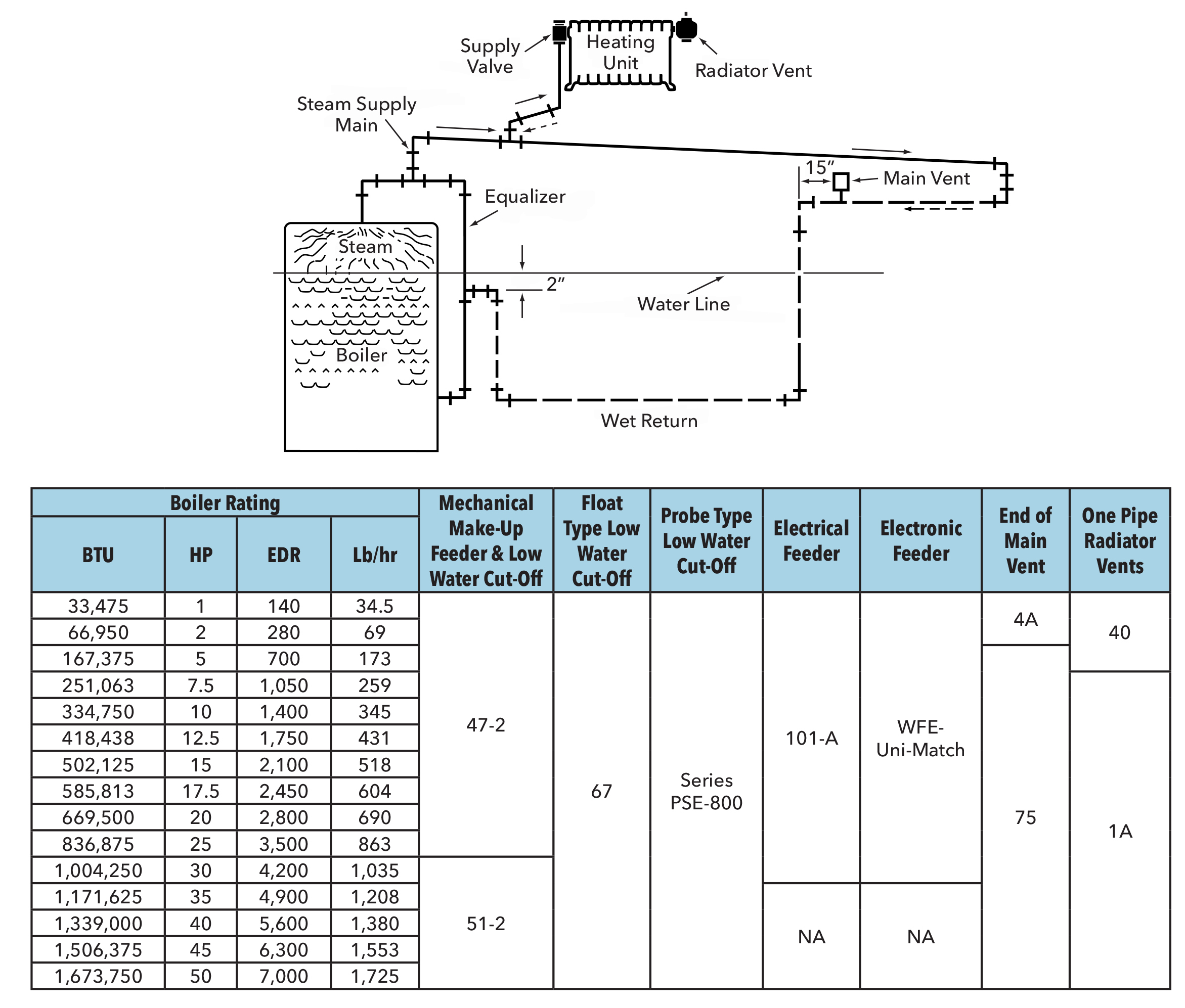

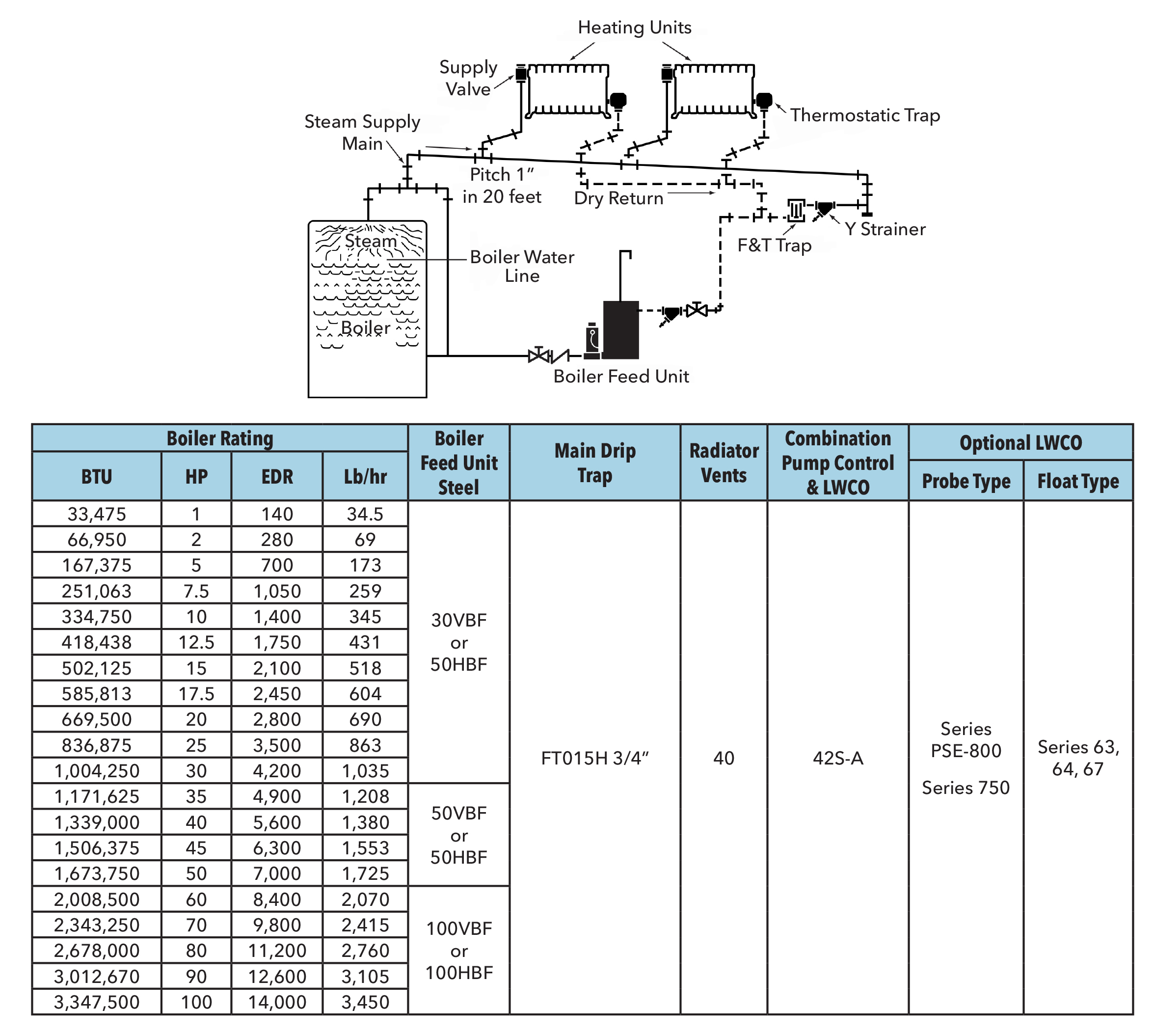

Piping layout and suggested product for one pipe gravity return systems based on system size

Gravity Return Systems

- All steam boilers are shipped from the factory with aLWCO. This could be a 67 or a ‘PSE’ unit, which you can specify when ordering the boiler.

- A 47-2 feeder/LWCO could be installed in place of the factory supplied LWCO on boilers less than 250,000 BTU.

- For boilers over 250,000 BTU, the factory supplied LWCO should be left in place as a secondary LWCO when installing a 47-2 or 51-2 feeder.

- Voltages of feeders, 101A and WFE Uni-Match, should be the same as the voltage at the LWCO cut-off they are being controlled by. For example, purchase and install a WFE-24 for installation on a boiler with a PSE-802-24 LWCO.

- The 67, 64 or series PSE-800 LWCO operates the electrical make-up water feeder and serves as a LWCO.

- We recommend that systems with 10 horsepower or larger boilers use a boiler feed unit.

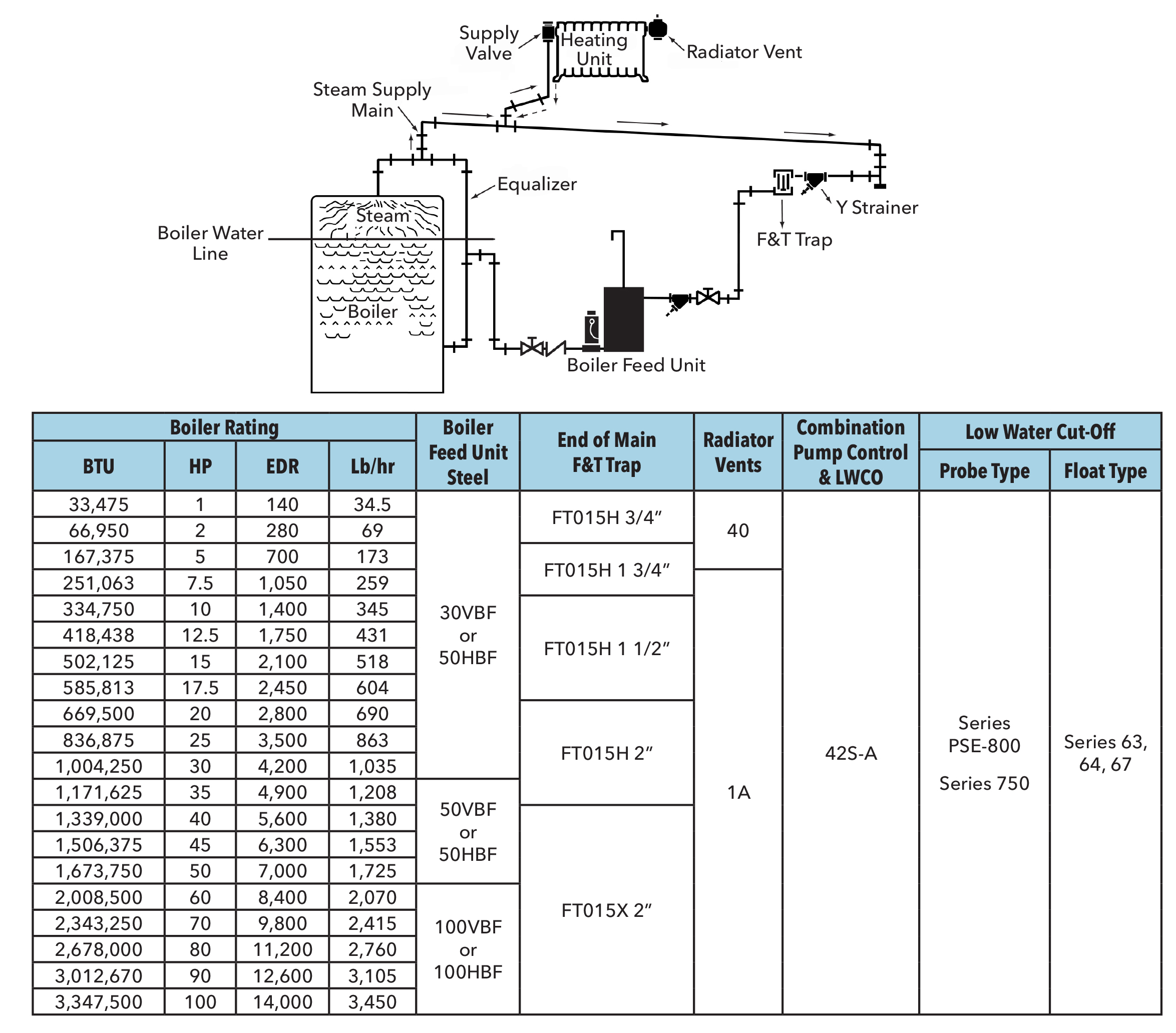

Piping layout and suggested product for one pipe pumped return systems based on system size

Pumped Return Systems

- All steam boilers are shipped from the factory with a LWCO. This could be a 67 or a ‘PSE’ unit, which you can specify when ordering the boiler.

- A 47-A Pump Controller/LWCO can be installed in place of the factory supplied LWCO on boilers less than 250,000 BTU. The 42S-A is connected to the boiler utilizing the sight glass tappings.

- For boilers over 250,000 BTU, the factory supplied LWCO should be left in place as a secondary LWCO when installing a pump controller/LWCO such as the 42S-A (sight glass tapping installation) or 42S (equalizing pipe installation).

- For any motor larger than 1/3 HP, a motor starter should be used to stop/start the pump to prolong the life of the switches in the M&M pump controller.

- The boiler feed units are selected for 10-minute storage, some applications may require a larger tank. Horizontal units are also available which provide a lower inlet connection.

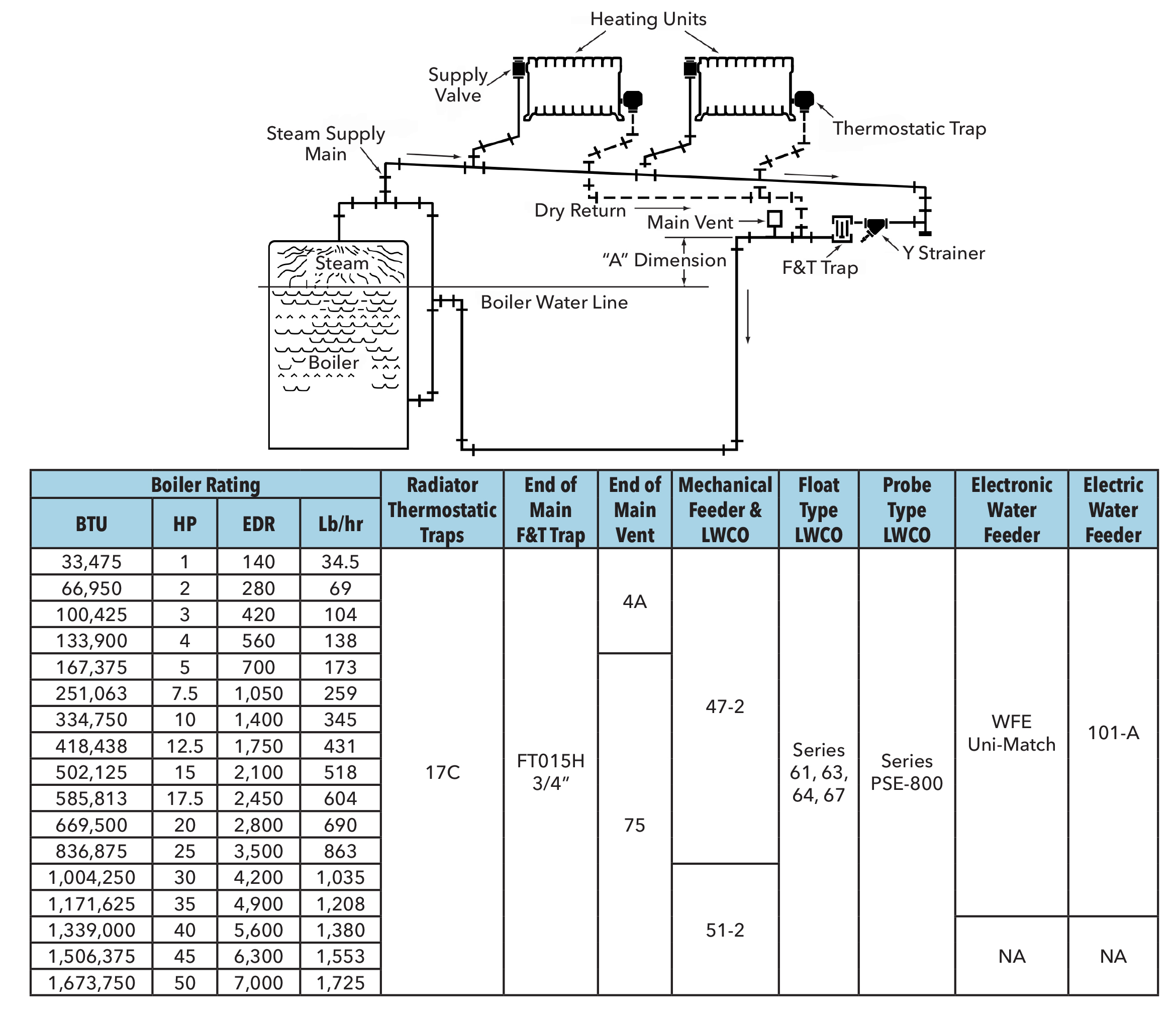

Piping layout and suggested product for two pipe gravity return systems based on system size

Gravity Return Systems

- All steam boilers are shipped from the factory with a LWCO. This could be a 67 or a ‘PSE’ unit, which you can specify when ordering the boiler.

- A 47-2 feeder/LWCO could be installed in place of the factory supplied LWCO on boilers less than 250,000 BTU.

- For boilers over 250,000 BTU, the factory supplied LWCO should be left in place as a secondary LWCO when installing a 47-2 or 51-2 feeder.

- “A” Dimension. Pressure Drop + Static Head + Safety Factor. Typically 26-28”.

- Voltages of feeders, 101A and WFE Uni-Match, should be the same as the voltage at the LWCO cut-off they are being controlled by. For example, purchase and install a WFE-24 for installation on a boiler with a PSE-802-24 LWCO.

- The 67, 64 or series PSE-800 LWCO operates the electrical make-up water feeder and serves as a LWCO.

- We recommend that systems with 10 horsepower or larger boilers use a boiler feed unit.

Piping layout and suggested product for two pipe pumped return systems based on system size

Pumped Return Systems

- All steam boilers are shipped from the factory with a LWCO. This could be a 67 or a ‘PSE’ unit, which you can specify when ordering the boiler.

- A 42S-A Pump Controller/LWCO can be installed in place of the factory supplied LWCO on boilers less than 250,000 BTU. The 42S-A is connected to the boiler utilizing the sight glass tappings.

- For boilers over 250,000 BTU, the factory supplied LWCO should be left in place as a secondary LWCO when installing a pump controller/LWCO such as the 42S-A (sight glass tapping installation) or 42S (equalizing pipe installation).

- For any motor larger than 1/3 HP, a motor starter should be used to stop/start the pump to prolong the life of the switches in the M&M pump controller.

- The boiler feed units are selected for 10-minute storage, some applications may require a larger tank. Horizontal units are also available which provide a lower inlet connection.

Domestic pump and Hoffman Specialty pump has a complete line of condensate transfer pumps, boiler feed pumps and vacuum return units

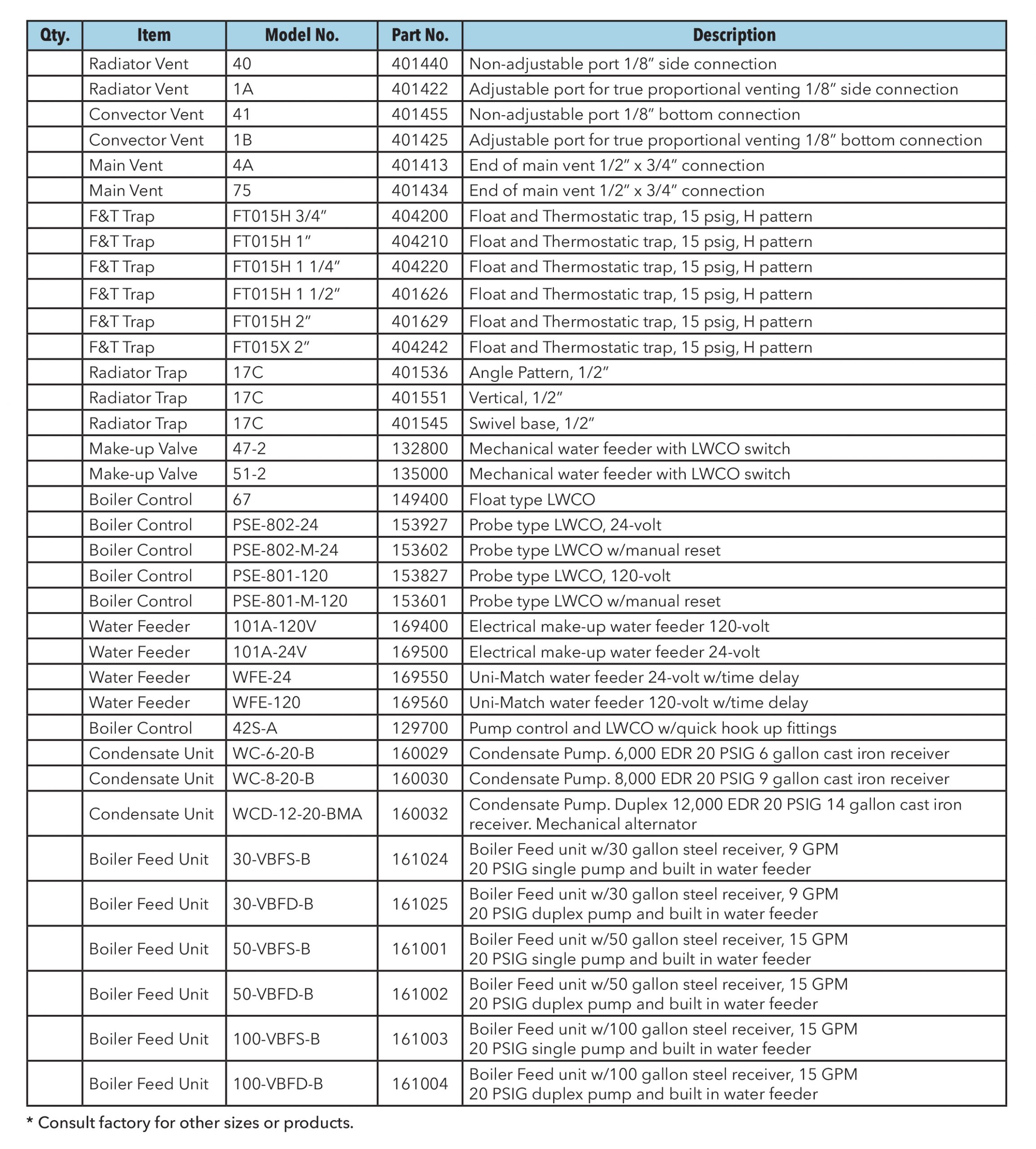

Quick selection materials list with part numbers and description.

Xylem offers the most complete line of products needed for steam systems. The SteamTeam includes Bell & Gossett Domestic Pump, Hoffman Specialty and McDonnell & Miller.

Domestic Pump and Hoffman Specialty

Provides the full line of condensate transfer equipment including condensate transfer units, boiler feed units, vacuum heating units, clinical vacuum units and low NPSH pumps.

Hoffman Specialty

Offers a complete line of steam traps, regulators, vents and accessories.

McDonnell & Miller

Delivers reliable performance and safety in boiler and level control products for over 95 years.

Click here to download the January 2020 SteamTeam Newsletter