Steam Vapor/Vacuum Systems

Volume 7/ Issue 2/ April 2020

Back in the days of coal and wood fired boilers, heating contractors used vacuum air vents to help them get the maximum efficiency out of their steam heating systems. They called these old systems “Vapor/Vacuum,” and the principle that made them work was a simple one: At very low pressure, steam takes up about 1700 times more space than water. When that steam condenses, it will create a vacuum if air can’t get back into the system. The old timers let the steam expand naturally. It pushed air ahead of itself, through the vacuum vents and out of the system. When the steam condensed in the radiators, it contracted to 1/1700th its size. Air couldn’t reenter the system through the vacuum vents because they have check valves at their outlets. If the piping was tight, a deep vacuum would form throughout the system. The nice thing about a vacuum is that it lowers the boiling point of water. If the system was set up right, a vapor/vacuum system could continue to make steam, even after the water temperature dropped as low as 140ºF. The old timers could take advantage of every bit of heat from the coal or wood fire as it burned down to embers. They wasted almost nothing. However nowadays most of us fire our steam boilers with gas or oil. Coal and wood fired boilers are still around, but they’re the exception to the rule.

Natural gas and oil are convenient fuels however they’re not a good choice for systems using vacuum vents because gas and oil burners cycle on and off. This ON/OFF cycling creates problems in systems that have vacuum vents. The vacuum quickly forms when the burner shuts off. Any air that doesn’t get vented on the first cycle expends greatly, blocking the movement of the steam “vapor” to the radiators, and because gas and oil burners shut off completely between firing cycles, there’s no longer a hot bed of embers to keep the low temperature water boiling. When you mix vacuum vents with gas or oil burned boilers you usually end up with uneven heat through the building, condensate that doesn’t return quickly enough from the system, and that can lead to problems with overfilled boiler or flooded system.

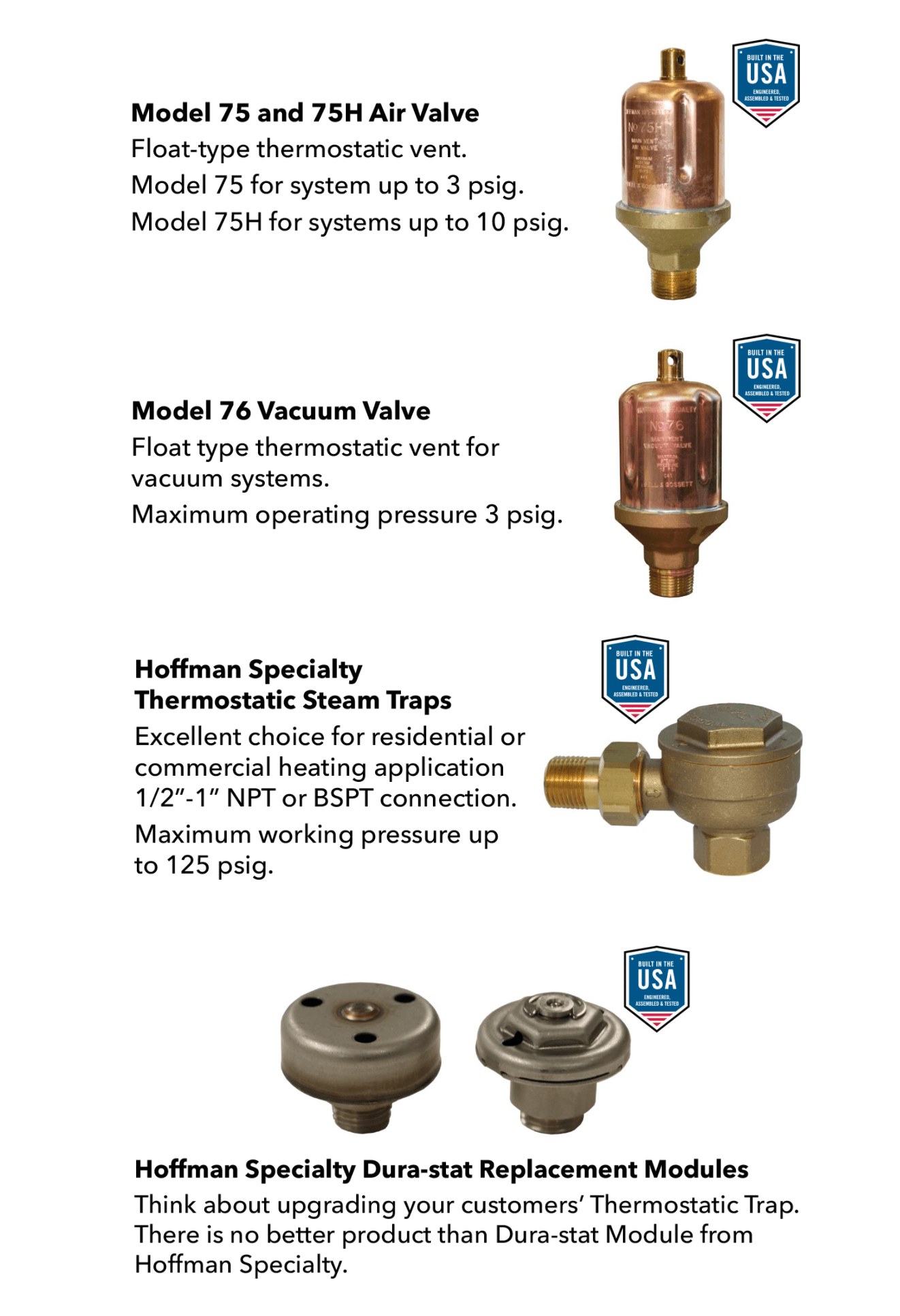

Hoffman Specialty stopped offering most of vacuum vents more than 25 years ago. Today, we only offer one vacuum vent – the #76 Main Vent. We continue to make this vent for the two pipe coal fired systems that remain.

If you have a two pipe, vapor/vacuum system running on gas or oil, you should be using our #75 Main Vents near the end of each dry return. The steam will push the air through the radiators, into the dry return and out through #75 Vent. The system won’t drop into vacuum as long as your radiator traps are working as they should, your old vapor/vacuum system will heat evenly at very low pressure. It usually takes no more than 12 ounces of pressure (0.75 psig). If you suspect your steam traps aren’t working as they should, test them with a contact thermometer or a temperature-sensitive crayon. You should see 10 to 15ºF drop in temperature across the thermostatic trap if it’s working correctly. If the traps are passing steam into the returns, you’ll have uneven heat, high fuel bills, boiler water level problems and water hammer noise.

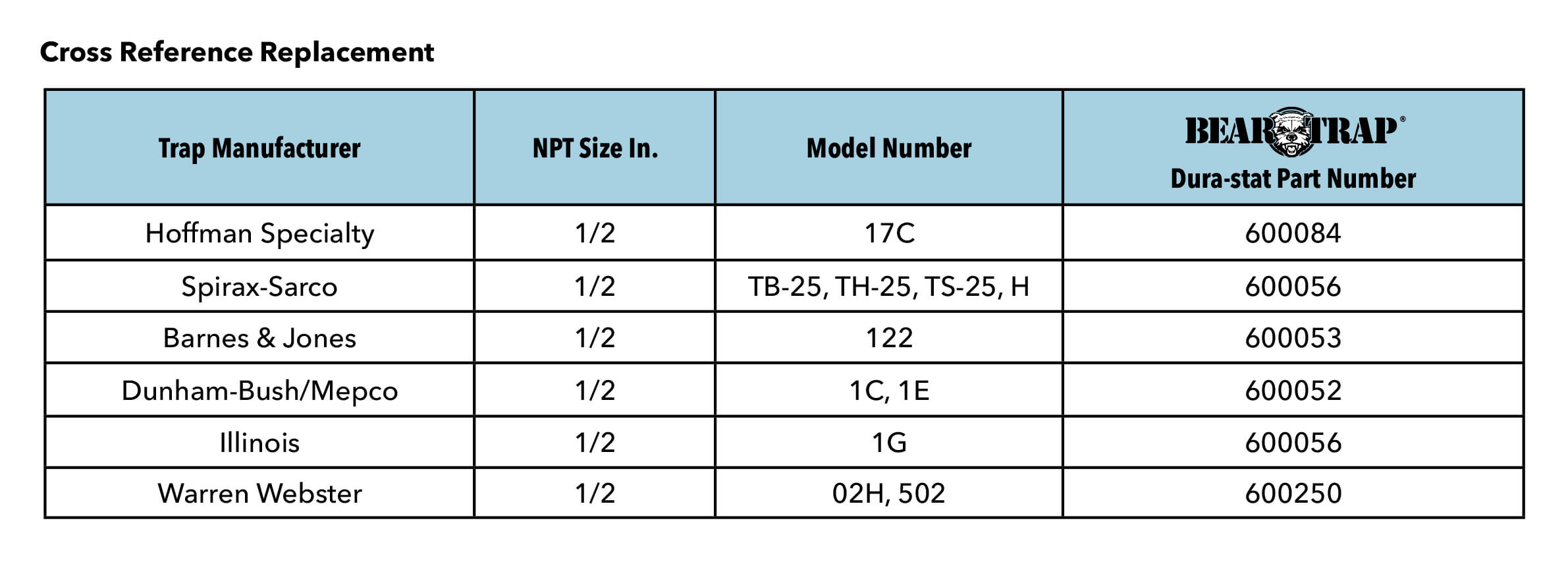

Steam traps are as important on those old coal or wood fired systems as they are on more modern oil or natural gas systems. You can replace those old steam traps with Hoffman Specialty Thermostatic Traps or repair with Hoffman Specialty Dura-stat® Replacement Module.

Our replacement parts are built to last for many years under the toughest conditions. They fit most old fashioned steam traps, and they pay for themselves in no time with fuel savings and even heat and comfort. Your customer will be thankful for these upgrades.

When you think steam system, think Hoffman Specialty. We have the parts and the specialized knowledge to help you solve those tough problems – we are always happy to help you and we appreciate your business!

For all your steam system needs please contact our Factory Representative.

Click here to download the April 2020 SteamTeam newsletter