Should I collect data on the condition of the cylinder in prestressed concrete cylinder pipe?

Prestressed concrete cylinder pipe (PCCP) has a reliable track record with generally low distress rates. Utilities can safely manage PCCP by detecting the early warning signs of a failure. So, what should utilities look for when assessing this type of pipe?

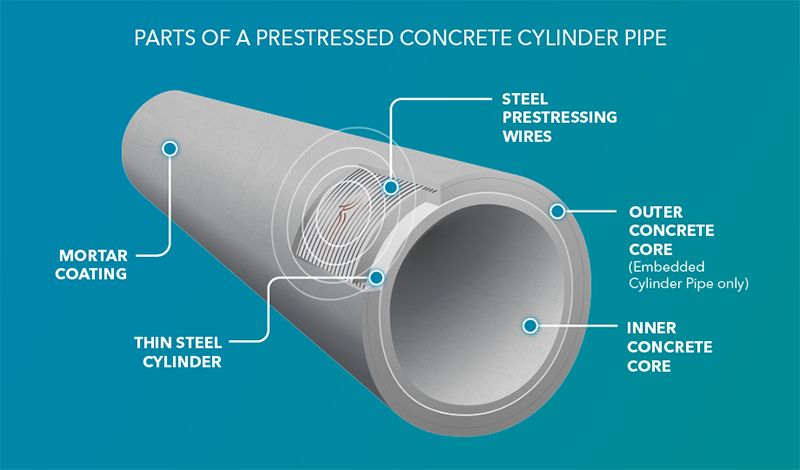

PCCP’s inner concrete core and thin steel cylinder act as a water barrier. Steel prestressing wires are wrapped under tension either directly around the cylinder (lined cylinder pipe) or around the outer concrete core (embedded cylinder pipe). The wires are the pipe’s primary structural component. They place the pipe in compression or “prestress” the concrete to offset the expected internal loads. A mortar coating further protects the steel components from corrosion.

“Failure of prestressing wires, and especially significant numbers of prestressing wires, should be recognized as fair warning that the pipeline is operating at a significantly reduced margin of safety and that its useful remaining life is finite.”

- Failure of Prestressed Concrete Cylinder Pipe, Water Research Foundation (2008)

Wire break damage is the principal failure mechanism for PCCP. Broken wire wraps are generally a reliable indicator of a pipe’s structural health, and there are proven electromagnetic and acoustic technologies for detecting and quantifying them. However, many in the industry are asking whether it’s also valuable to assess the steel cylinder.

More Data is Not Always Better

Utilities typically assess PCCP to identify distressed pipes, address pipes with an unacceptable level of risk, and extend the life of their pipeline. Ultimately, this can improve asset reliability and reduce lifecycle costs.

When a pipe is deteriorating, gathering additional data on the cylinder may seem like an attractive option. However, ask whether the additional data will change your management approach.

PCCP failures can have devastating consequences for communities. A pipe’s remaining service life is determined with less assurance as the number of broken wire wraps increases. Managing a deteriorating pipe to the end of its service life is unpredictable and comes with considerable risk. To do so safely requires a significant investment in more frequent inspection or continuous monitoring.

Risk tolerance and future life-cycle costs factor into decisions to repair or replace a pipe. However, it is often less expensive and lower risk to rehabilitate a pipe and extend the pipeline reinspection interval.

A pipe with broken wire wraps and steel cylinder corrosion

The Trouble with the Cylinder

In most cases, identifying cylinder wall loss is not worth the high cost and effort. The steel cylinder provides some structural strength to pipelines operating at low pressures. However, it is dangerous to rely on this, as transient pressures can be highly unpredictable.

Lined cylinder pipe is not likely to have significant, detectable cylinder corrosion without first experiencing broken wire wraps. Even then, only a pipe operating at low pressures will develop cylinder corrosion at length before failing.

In embedded cylinder pipe, the steel cylinder sits within two concrete cores. This makes the cylinder much more resistant to wall loss. Heavy wire break damage, cylinder expansion, and core cracking must all occur before corrosion can begin on the steel cylinder. At this point, failure is already imminent.

Additionally, predicting the structural capacity of the cylinder is difficult and doesn’t depend solely on wall loss. Factors such as varying manufactured thickness, weld defects, and bending stresses can all impact the cylinder’s integrity or burst pressure. A shear failure due to cantilever or bending stresses acting on the cylinder is much more likely than one caused by corrosion.

To date, remote field electromagnetic inspections have not proven effective at reliably identifying shear failures in the cylinder. There are more valuable approaches to assessing the pipe’s overall condition, including the cylinder. These methods complement electromagnetic detection of broken wire wraps.

Visual and sounding inspections can identify longitudinal cracks and loss of concrete core compression — late-stage indicators that the pipe is nearing its yield limit. Visual inspection can also identify circumferential cracks and moisture seepage that can indicate a shear failure. A relatively low-effort inline acoustic inspection can detect leaks resulting from corrosion or shearing of the steel cylinder, third-party damage, or a loss of joint integrity.

In conclusion, extending a pipe’s service life based on the cylinder’s structural capacity is extremely risky. In most cases, it is more cost effective to repair a pipe with significant deterioration than to invest in additional inspection and monitoring.