Responding to water and wastewater pipeline emergencies

U.S. and Canadian utilities experience an annual average of 11.1 breaks per 100 miles of pipe, according to a 2023 Utah State University study. When a water main breaks, protecting the community, reducing the impact of the break, and returning the line to service are top priorities.

For critical transmission mains, adding inspection to this list could prevent another catastrophic failure.

“Pipeline deterioration is not uniform, but it is worthwhile to inspect the surrounding area while the pipeline is out of service,” says Alan Bair, Senior Manager of Infrastructure Solutions at Xylem.

That area is subject to the same environmental conditions as the failed pipe. It could be a hot spot for corrosive soils, for example. Adjacent pipes were also likely built by the same manufacturer and installed under the same construction contract. Failures often result from manufacturing defects or poor design and installation.

“With the pipeline excavated, dewatered, and open, it’s easier to get people or tools in to check for signs of distress,” Alan says. “If utilities find other damaged pipes, there’s operational and cost efficiencies to repairing the pipeline during the same shutdown.”

Identifying and addressing areas of weakness also protects the pipeline during startup, when there is additional stress on the line.

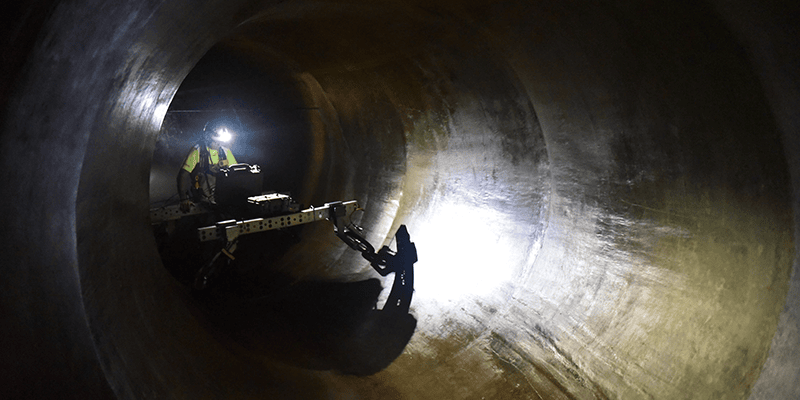

Piloted electromagnetic and visual inspection with Pure Technologies’ PipeWalker platform

Alan recommends taking samples of the pipe and surrounding environment. Forensic analysis can help utilities determine the likely cause of a break, remedy contributing factors, and determine if this type of damage is possible at other locations on the pipeline.

“Instead of just patching the hole, the goal is to understand risk and get ahead of the next failure,” Alan says. “Once utilities are out of emergency mode, they should consider assessing the full line.”

Sometimes a failure is indicative of a bigger problem, like hydrogen embrittlement. In many cases, we find that the vast majority of the pipeline is in serviceable condition.

Condition assessment shows where and how much the pipeline has deteriorated. It also gives utilities data to make informed decisions about the future of the asset – is it more economical to replace the pipeline or can it be managed through a cycle of reinspection and repair?

“Ultimately, we want to help utilities build a proactive pipeline management strategy that anticipates maintenance needs.” Alan says.

Even with the best laid plans, utilities can face unexpected integrity threats — from third party damage to geotechnical hazards to extreme weather. Leaks are another common pipeline emergency. Left unchecked, they can lead to significant water loss, damage to the pipeline and surrounding infrastructure, and eventually failure.

“There’s cases where utilities know they have a leak, but they can’t pinpoint it’s location,” Alan says. “An inline leak inspection is a relatively low-effort way to locate leaks on transmission mains with very high confidence.”

We’re here to help

Where pipeline integrity is in question, Xylem has the regional presence to mobilize quickly and perform an emergency assessment. We can also provide additional emergency services like dewatering and designing and installing a bypass.

Even if a utility responds to distribution main breaks frequently, they may have less experience with large-diameter pipe failures. The Utah State University study referenced earlier shows that transmission mains fail five times less often than distribution mains.

Xylem’s pipeline experts are a resource to help utilities face their toughest integrity challenges. We can evaluate the immediate area of concern, provide emergency repair recommendations and solutions, and perform quality assurance and control checks on repairs in the field.

“We collaborate with utilities to solve complex, often time-critical pipeline challenges every day,” Alan says. “Utilities can lean on our engineering expertise to help guide next steps for the asset and the network.”

The bottom line: if you have a pipeline challenge or emergency, reach out to see how Xylem can help.