It looks like you are coming from United States, but the current site you have selected to visit is Zambia. Do you want to change site?

- Sign In

- Register

- Request Info

- Find a Location

-

Enable high contrast mode

-

- Select language

- Algeria

- Angola

- Anguilla

- Antigua and Barbuda

- Argentina

- Australia

- Austria

- Azerbaijan

- Bahamas

- Bahrain

- Barbados

- Belgium

- Belize

- Benin

- Bermuda

- Bolivia

- Botswana

- Brazil

- British Virgin Islands

- Bulgaria

- Burkina Faso

- Burundi

- Cabo Verde

- Cameroon

- Canada English

- Canada Français

- Cayman Islands

- Central African Republic

- Chad

- Chile

- China

- Colombia

- Comoros

- Congo

- Congo, Republic of the

- Costa Rica

- Cote d'Ivoire

- Croatia

- Czech Republic

- Denmark

- Djibouti

- Dominican Republic

- Dominicana

- Ecuador

- Egypt

- El Salvador

- Equatorial Guinea

- Eritrea

- Eswatini

- Ethiopia

- Europe

- Finland

- France

- Gabon

- Gambia

- Germany

- Ghana

- Greece

- Grenada

- Guadeloupe

- Guatemala

- Guinea

- Guinea-Bissau

- Guyana

- Haiti

- Honduras

- Hong Kong

- Hungary

- India

- Indonesia

- Iraq

- Ireland

- Israel

- Italy

- Jamaica

- Japan

- Jordan

- Kazakhstan

- Kenya

- Korea

- Kuwait

- Lebanon

- Lesotho

- Liberia

- Libya

- Lithuania

- Madagascar

- Malawi

- Malaysia

- Mali

- Martinique

- Mauritania

- Mauritius

- Mexico

- Mongolia

- Montserrat

- Morocco

- Mozambique

- Namibia

- Netherlands

- New Zealand

- Nicaragua

- Niger

- Nigeria

- Norway

- Oman

- Panama

- Paraguay

- Peru

- Philippines

- Poland

- Portugal

- Puerto Rico

- Qatar

- Romania

- Rwanda

- Saint Kitts and Nevis

- Saint Lucia

- Saint Vincent and the Grenadines

- Sao Tome and Principe

- Saudi Arabia

- Senegal

- Seychelles

- Sierra Leone

- Singapore

- Slovakia

- Somalia

- South Africa and Sub-Saharan Africa

- South Sudan

- Spain

- Sudan

- Sweden

- Taiwan

- Tanzania

- Thailand

- Togo

- Trinidad and Tobago

- Tunisia

- Turkey

- U.A.E

- U.S. Virgin Islands

- Uganda

- Ukraine

- United Kingdom

- United States

- Uruguay

- Uzbekistan

- Venezuela

- Vietnam

- Yemen

- Zambia

- Zimbabwe

Bilge Pumping for Large & Small Boats

What is a bilge pump and why do I need one?

Whether from a propeller shaft packing gland, a leaky portlight, loose seams in a wooden boat, melting ice from a cooler, or many other sources, every vessel ends up with unwanted water in the bilge that will quickly turn rancid. Leaving large amounts of water in the bilge can have several undesirable effects on your boat, including destabilizing it, lifting spilled fuel and distributing it throughout the bilge (where it can attack, among other things, the insulation on electrical wiring) and promoting the development of osmotic blisters in fiberglass hulls.

To deal with bilge water, most modern boats are fitted with a network of pumps to service the water out of different pockets within the bilge. With various types of bilge pumps available, including electric, manual, and engine-driven solutions, we’re certain to have the right type of bilge pump to meet your needs.

What type of electric bilge pump is best for my boat?

Xylem’s Jabsco and Rule brands offer three different types of electric bilge pumping solutions: submersible pumps, flexible impeller pumps, and diaphragm pumps.

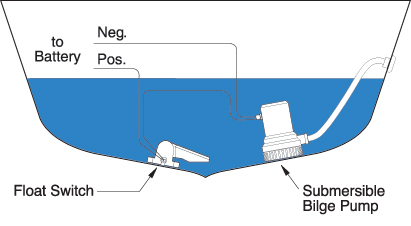

Submersible electric pumps in the lowest part of the bilge

By far the most popular type of electric bilge pumps, submersible bilge pumps give very high outputs, are cost effective, have low amp draw and are easy to install. They are designed to fit in the lowest part of the bilge and only require discharge pipe work and electricity supply. However, flow rates decrease as the discharge head increases, so check our recommended maximum discharge heads and if in doubt, always increase the size of the pump.

Although our submersible bilge pumps can be run dry for up to two hours, pump life can be extended by avoiding dry running whenever possible. All submersible bilge pumps can be operated using a float or hydro-air switch, and remotely controlled outside the bilge compartment by using a Rule switch panel.

Flexible impeller bilge pumps for debris handling capabilities

Flexible impeller pumps make excellent bilge pumps, principally because of their ability to handle bilge debris without damage. Flexible impeller pumps also offer the benefits of good flow, low cost, low size and weight, and are easily serviced and maintained. Most flexible impeller pumps must not be run dry, as this will damage the impeller and require replacing. However, some of our Puppy Series models allow a maximum of 10 minutes dry running after initial prime.

Flexible impeller pumps can be operated using a float or hydro-air switch, and remotely controlled from outside the bilge compartment. There is a wide range of flexible impeller pumps to choose from, giving a range of flows, discharge heads and self-priming options for applications such as ballast transfer, bait tank circulation and deck wash duties.

Diaphragm pumps for shallow bilge boats

Diaphragm pumps are excellent for shallow bilge boats, where the water left behind by other types of pumps will slop from side to side. With the small size of inlet plumbing, they are very effective as bilge pumps, removing all but the last drops of water. Diaphragm pumps can be run dry, which removes the need to watch overboard outlets while the pump is running. The ability to self-prime means they can be mounted in an easily accessible, high and dry location to simplify installation and improve serviceability. Most models in the line are supplied complete with a Pumpgard strainer to protect the pumps from bilge debris.

Manual bilge pump solutions

Manual bilge pumps are the traditional mainstay of small craft bilge pumping systems and can offer surprisingly good flow rates, as well as a variety of installation options. Yacht racing rules state that at least one pump must be capable of being pumped from the cockpit with all hatches shut. The best way to accomplish this is with a through deck kit which allows the pump to be installed safely below decks while the operator pumps from above. A well-designed manual bilge pump is very hard to block due to its large bore hose and valves and one piece diaphragm. The larger pumps in the Jabsco line of manual bilge pumps are also suitable for ballast and waste transfer.

Engine-driven bilge pump solutions

Jabsco engine-driven pumps are probably the strongest and most reliable pumps produced today. Combined with other benefits such as self- priming and high flow rates, these pumps are now the firm favorites of commercial and professional mariners worldwide. All the pumps are easily maintained and can fulfill a variety of duties onboard both modern and classic vessels.

Either manual or electromagnetic flexible impeller clutch pumps are ideal for bilge pumping. Each type of clutch has different benefits from the other. Manual clutches will operate as long as the engines are still running, which provides added security when operating as a secondary bilge pump. Electromagnetic clutches can be operated remotely via float or hydro-air switches, while fitting a vacuum switch eliminates all risk of dry running damage. However, electromagnetic clutches will only engage as long as electrical power remains available.

A long tradition of manual & electric bilge pump innovation

Rule and Jabsco bilge pumps and accessories have a long history of innovation and quality and are trusted to keep boats dry and safe. More innovations have come from Rule and Jabsco than any other manufacturer, which is why they are the most popular brands of bilge pumps in the world. Today, these legendary brands offer the broadest range of bilge pumps available to recreational boat owners.

Learn more with Xylem

-

Solve Chronic Bilge Water

Solve Chronic Bilge WaterLearn where bilge water comes from and how to remedy it.

-

Airlock in Bilge Hose

Airlock in Bilge HoseOur team explains the impact of an airlock or water trap on a bilge hose.

-

Identifying Bilge Pump Wires

Identifying Bilge Pump WiresThis video walks through the purpose of each wire on the Rule bilge pumps.

-

Sealing Bilge Pump Wires

Sealing Bilge Pump WiresLearn how to seal the manual wire on our bilge pumps if you’re not using the manual override option.

-

Winterizing an impeller style bilge pump

Winterizing an impeller style bilge pumpHow to winterize a Jabsco impeller pump.

-

Getting a Rule-Mate Pump Back to Regular Mode

Getting a Rule-Mate Pump Back to Regular ModeLearn how to get a Rule-Mate pump out of safe mode.

Contact an Expert

Whether you would like additional information or are interested in getting a quote, we're here to help.

All fields required.

Looks like you are offline, your form will be sent as soon as you get back online.

- Privacy Policy

- Terms & Conditions

- Update Preferences

- Copyright 2025 Xylem. All Rights Reserved.