A Day in the Life: PipeDiver Inspection with Pressurized Insertion & Extraction

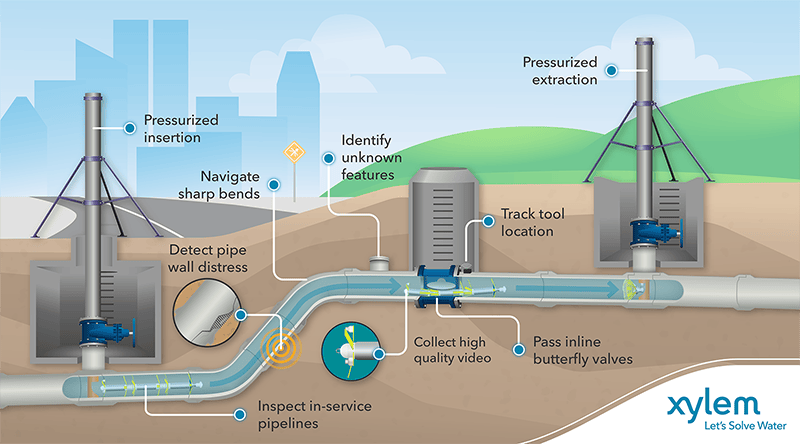

Join me onsite for a raw water pipeline inspection with the PipeDiver® platform. I recorded this video in the field to show how we use specialized standpipes to launch and remove the PipeDiver from a live pipeline without disrupting water service.

Water infrastructure runs 24/7, delivering a vital supply of water to homes and businesses around the world. Without pipelines, modern life would come grinding to a halt. Yet data on these critical assets is lacking.

Inspecting large pressure pipelines is challenging. Buried infrastructure is difficult to access, and sometimes, it’s not feasible to remove pipelines from service. Pure Technologies, a Xylem brand is focused on making actionable pipeline condition data more accessible to water and wastewater utilities.

Ultimately, this data helps pipeline owners optimize repair planning and long-term asset management.

We’re always looking for ways to make the inspection process easier on our utility partners and the communities they serve. Our PipeDiver® and SmartBall® platforms inspect pipelines while they remain in service.

In the field, PipeDiver often attracts the attention of bystanders with its blue sail, yellow fins, and long, flexible body — a free-swimming design refined for navigating bends, tees, and even inline butterfly valves.

Towering hydraulic standpipes give people another reason to stop. These specialized tubes enable the team to launch and extract the PipeDiver from pressurized pipelines under live operational conditions.

This means no downtime for customers and no need to dewater your large-diameter assets. For perspective, one mile of pipeline 36 inches in diameter contains nearly 280,000 gallons of water — enough to supply a community of 2,800 people with water for a day!

An overview of a PipeDiver inspection with pressurized insertion and extraction

Once inside the pipeline, PipeDiver travels with the flow of water for up to 25 miles. The tool inspects each individual pipe for key signs of deterioration to guide repairs and prevent failures. It detects and locates broken prestressing wire wraps in concrete pressure pipe and areas of corrosion in metallic pipelines.

At the end of the inspection, a net secures the PipeDiver and pulls it into the extraction standpipe. The team closes an isolation valve below the standpipe, drains the equipment, and detaches it from the pipeline.

Not all pipeline operations or system designs are suitable for a pressurized deployment. No matter how the tool is deployed, we collaborate closely with our clients to minimize disruption and preparatory civil work. We use custom equipment and alternate deployment methods when pressurized insertion and extraction isn’t feasible or preferred. Our team has inspected over 2,000 miles of pipe with the PipeDiver platform and has experience getting the tool into and out of pipelines all over the world.