In a competitive environment, it is essential that a “live” product like beer reaches the consumer in prime condition in order to retain its flavor and the characteristics that make it unique, just as the brewer intended. The beer also needs to be dispensed at a rate that supports venue business levels, and the skill level of the serving staff behind the bar.

To meet the above requirements, one of the most effective methods of packaging beer is in stainless steel or aluminium kegs. Kegs transport and dispense mass quantities of beer without impacting its quality or taste by protecting it from exposure to oxygen and sunlight. Kegs also allow the beer to be dispensed easily and quickly for more fast and efficient service.

Because space in the bar is often limited, kegs are normally stored remote from the bar area, so the beer needs to be moved from the cellar or storeroom to the tap on the bar. However, the taste of every beer dispensed from a keg that’s stored remotely can be hit or miss depending on the distance it needs to travel and the temperature at which it has been stored.

With so many variables at play, having the right beer dispense system is critical to ensuring the perfect pour – from the barrel to the bar, every time.

Did you know?

Beer has a natural carbonation level that is essential for texture and taste.

The point where the pressure on the beer is just enough to keep the CO2 in the beer is called the ‘equilibrium pressure’.

If the beer is maintained at equilibrium pressure, its texture and taste will be exactly as the brewer intended it to be.

Perfecting the Pour

Typically, systems that push beer through dispensing systems are CO2 gas or blended gas assisted, which is why it can be challenging to perfect the pour. To transport the beer from the keg to the bar, gas pressure above the level required to maintain the beer at brewery standard is applied to the top surface of the beer, pushing the beer through the tubing to the bar.

Head pressure, as recommended by the brewer, effectively delivers the beer to the glass over short line distances. The further the keg is from the bar, the greater the applied gas pressure needs to be – this means recommended head pressure plus added pressure transports the beer from the keg to the glass. Whenever the head pressure applied to the beer exceeds the equilibrium pressure recommended by the brewer, it is easy for the incorrect pressure to be set. This results in conditions where the pressure is either too high or too low.

Over time, excess pressure leads to more CO2 being absorbed by the beer. This is known as ‘over carbonation’ and has two major drawbacks:

- Foaming: CO2 released on dispense leads to too much foam on the beer head, making it difficult to dispense.

- Flavor: Too much foam impacts the texture and taste of the beer, resulting in a negative experience for the consumer.

The opposite of ‘over carbonation’ is under carbonation or flat beer. This occurs when the pressure applied to the keg is too low. In ‘under carbonation’ conditions, the CO2 gas in the beer escapes in the keg until the equilibrium pressure is reached. The result is a flat beer, which destroys the taste and texture of the beer, spoiling the experience of the end customer.

The beer pump was developed to overcome such challenges. Unlike traditional (non-pump) dispense methods, the pressure on the keg remains constant at the equilibrium pressure. Maintaining constant equilibrium pressure on any keg means the taste of the beer remains exactly as the brewer intended and the consumer gets a distinct, satisfying, truly enjoyable glass of beer with every pour.

Did you know?

If every faucet on a bar wastes just one drip tray of beer each day, and that bar or restaurant trades for 312 days in a year, an equivalent of 58.5 gallons (468 pints) of beer are wasted.

Push and Pull Pumping

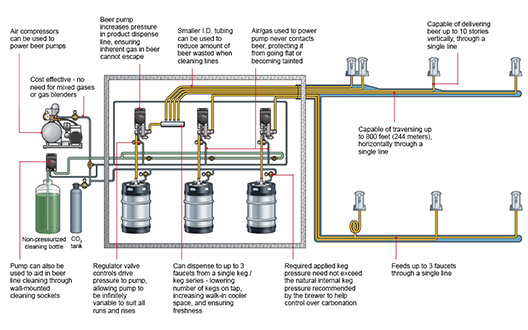

The use of beer pumps, particularly in environments where excess top pressure is required to traverse a distance, allows an installer and operator to maintain equilibrium pressure in any given circumstance. There is no need to put extra pressure on the beer to effectively move it through the system. Instead, ‘drive’ pressure is applied to the pump to move the beer. The drive pressure effectively acts like a car accelerator – the more you put into the pump, the quicker it operates.

Beer pumps consist of an air chamber, where the drive pressure comes in, and two wet chambers where the beer passes through. The two wet chambers are separated by seals known as diaphragms. Because of this design, the drive gas never comes into contact with the beer. A special shuttle valve forces the air pressure behind each of the diaphragms in turn, allowing one piston to gently suck the beer in, while the other pushes it out the other side.

This push-pull action draws the beer from the keg and gently pushes it through the tubing to the bar. When the dispense tap is opened, pressure in the line drops below the drive pressure in the air chamber so the pump runs, feeding the beer line to the bar. When the faucet is closed, the pressure in the line rises to a point where the beer pump stops. It remains stopped until the faucet is opened again to dispense beer.

Benefits of Beer Pumps

- Beer is maintained at equilibrium pressure, preventing over carbonation

- Beer can be moved over longer distances, allowing kegs to be stored remotely

- Dispense speed can be adapted to meet business demand and skill level of serving staff

- Dispense speed and presentation is consistent with every pour

- The perfect pour prevents beer wastage, saving money

- Less CO2 is used as the beer pump can be driven using a compressor