MAKE PCCP YOUR MOST RELIABLE ASSET.

Prestressed concrete cylinder pipe (PCCP) is widely used in large, critical water pipelines and force mains. It is a very reliable pipe material. Though rare, PCCP failures are often catastrophic. These explosive failures don’t just damage the water infrastructure. They can also damage property, endanger the public, interrupt the water supply, and harm the utility’s reputation. A large-diameter pipe failure can cost a community well over $1 million in direct and societal costs.

Concern over sudden failures causes many PCCP owners to consider replacement. However, PCCP pipelines are very dependable compared with other materials. Pure Technologies, a Xylem brand has collected two decades of PCCP data. Only 4% of inspected pipes show signs of distress. PCCP also has one of the lowest leak rates of any pipe material. With condition assessment data, utilities can make PCCP pipelines even safer and more reliable. Our approach to PCCP management can virtually eliminate the risk of failure while maximizing pipeline life.

EXTEND LIMITED CAPITAL BUDGETS.

Replacing a pipeline is disruptive and expensive. Plus, most PCCP in the ground today is still in good condition. Only a small fraction of pipes show signs of damage. Even fewer pipes need immediate repair or replacement. Leading pipeline owners are safely managing PCCP for 10 to 20 percent of full replacement costs.

![]()

![]()

AVOID FAILURES ON CRITICAL PIPELINES.

Critical pipelines are vital to communities and have severe consequences when they fail. Where failure is unacceptable, inspection and monitoring can detect potential problems before essential pipelines break. Proactive repairs extend pipeline life and cost far less than a failure.

ELIMINATE GUESSWORK.

Pipelines are too important and expensive for assumptions about their health. Condition assessment eliminates guesswork and provides data for confident decision making. This helps utilities focus resources on the right pipes so communities are safer and capital budgets go further.

![]()

LEADERS IN CRITICAL PIPELINE ASSESSMENT.

Pure Technologies has inspected over 7,000 miles (11,250 km) of PCCP and monitored more than 830 miles (1,340 km). Our best-in-class approach is built on 20 years of experience with some of the largest PCCP owners in the world. We have developed a suite of proven technologies for inspecting and monitoring PCCP. Using these technologies, our team has completed thousands of projects around the world. We know what it takes to get tools in, through, and out of complex pipelines. This operational experience ensures quality project management and professional inspection delivery. We also draw on the largest PCCP data repository for advanced engineering analyses. With an unmatched breadth of experience and data, Pure Technologies can help utilities avoid failures, extend the life of PCCP assets, and make informed pipeline management decisions.

LOWER RISK WITH LESS WASTE.

Pipeline failures waste valuable utility resources and erode public confidence. However, replacing entire pipelines based on age or past failures may also be uneconomical. The U.S. EPA estimates a large percentage of replaced pipe still has remaining useful life. The best way to manage PCCP safely and cost-effectively is by identifying actual pipe condition. This enables utilities to make the smartest short- and long-term decisions about pipeline operations, repair, and replacement.

WHY ASSESS CRITICAL PCCP PIPELINES?

- Prevent catastrophic failures and avoid unplanned, emergency maintenance

- Track pipeline deterioration and make selective, proactive repairs

- Avoid premature pipeline replacement

- Inform long-term capital planning

- Reduce the consequences of failure with better valve control

- Balance risk reduction with the cost of mitigation strategies

SMARTER PCCP MANAGEMENT.

For large, critical PCCP pipelines, preventing even one failure can lead to a positive return on investment. When utilities avoid unnecessary replacement and manage PCCP assets to their full useful life, they can realize significant capital savings.

Condition data is key to making smart pipeline management decisions today and in the future. Condition assessment identifies which pipes to renew and which can continue operating safely.

Pure Technologies has helped utilities save billions of dollars by preventing failures and keeping good pipe in the ground longer. Learn how you can reduce risk and extend your utility’s capital budget by leveraging our proven technology, experienced operations team, and engineering expertise.

FIVE STEPS TO PROACTIVE PCCP MANAGEMENT.

Pure Technologies’ assessment approach leverages more than 20 years of dedicated PCCP experience. We partner with utilities to develop a condition assessment strategy that achieves their risk reduction goals. That strategy can cover a single critical pipeline or an entire network of assets. We work with utilities every step of the way to execute a successful inspection and deliver meaningful data.

Take the five steps below to reduce risk, extend pipeline life, and confidently manage PCCP for a fraction of full replacement costs.

STEP 1

RISK ASSESSMENT

Reducing risk is the main goal of most condition assessment programs. Risk includes the likelihood of a pipe failure and the consequences of that failure. Risk informs which pipes to inspect and what assessment methods to use.

STEP 2

IMPROVE SYSTEM CONTROL

Assessing and rehabilitating critical valves reduces emergency response time and consequence of failure. Working valves also benefit from routine pipeline maintenance and inline inspections. Learn how to regain control of your critical valves.

STEP 3

PIPELINE INSPECTION

Collect baseline condition data with inline leak detection and pipe wall inspection. Electromagnetic wall inspection tools detect broken wire wraps, the primary sign of PCCP deterioration. Our experienced team and flexible tools can meet many operational needs.

STEP 4

CONTINUOUS MONITORING

PCCP pipelines are often critical mains with no tolerance for failure. Continuous monitoring is ideal for high-risk pipelines. The system alerts utilities to wire breaks in near real time. Long-term structural health monitoring also strengthens advanced analyses.

STEP 5

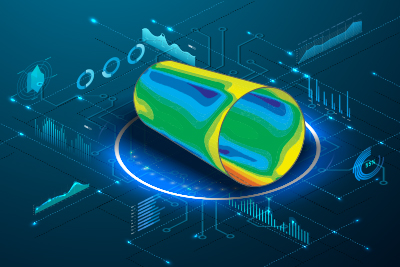

ADVANCED ANALYSIS

Advanced analyses use inspection and monitoring data to predict how pipes respond to stress and degrade over time. This information guides decisions about when to reinspect, repair, or replace PCCP pipelines.

PCCP MANAGEMENT TOOLBOX

INLINE LEAK DETECTION

Pinpoint leaks and gas pockets and map pipelines without disrupting service. The free-swimming SmartBall® platform is easy to deploy and excels at long-distance water main and force main inspections. The tethered Sahara® platform is ideal for complex water distribution networks and captures live video in the pipeline.

INLINE WALL ASSESSMENT

Identify broken wire wraps on a pipe-by-pipe basis with our electromagnetic inspection platforms. The free-swimming PipeDiver® platform inspects water and wastewater pipelines while in service. The modular PureRobotics® crawler accommodates an array of sensors for inspecting depressurized water pipelines. Gain high-resolution condition data and a visual inspection with the piloted PipeWalker™ platform for dewatered pipelines.

PIPELINE MONITORING

Pure Technologies’ SoundPrint® AFO monitoring system continuously detects and locates wire breaks in PCCP. This advanced warning system and our dedicated support team help utilities prevent large-scale failures. Utilities can access monitoring data any time, on any device via a secure, map-based web portal. Utilities can also seamlessly integrate the data with their own management systems using API.