How Threat Monitoring Can Save Pipeline Operators Time and Money

Pipeline damage can happen even with a robust integrity program in place. Third-party damage during excavation, natural disasters, and even material defects from manufacturing can put your pipeline at risk.

Proactive inspection and monitoring efforts can catch threats before they lead to a spill. However, once damage is identified, it’s important to understand the severity of the threat and whether an immediate repair is necessary.

Pipeline excavations and digs are costly endeavors that take time and resources. In this blog, we’ll explore how operators can monitor known threats for leakage with PureHM’s SmartBall platform. Using this technology, you can avoid expensive emergency repairs and coordinate planned maintenance with confidence.

Integrity Grey Areas

Threats range from cracks to internal and external corrosion. Significant individual or interacting threats may require immediate action to prevent a failure. For example, when wall loss reduces a pipe’s structural integrity below its specified minimum yield strength.

However, integrity decision making is not always straight forward. Depending on the type and severity of the threat, a pipeline could continue operating with increased vigilance.

Data provided by inline inspection tools can sometimes leave decision makers in the dark about next steps. This is where SmartBall can fill in the gap.

There are a variety of inline inspection (ILI) tools designed to identify different types of defects. However, even the most advanced tools can’t determine when a defect extends completely through the pipe wall.

Threat Monitoring with SmartBall

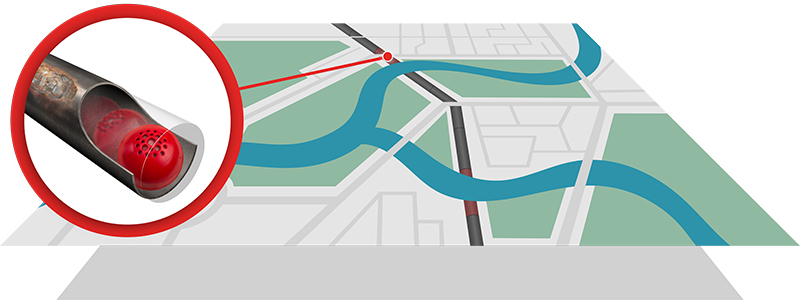

The SmartBall platform complements pipe wall inspection tools with its industry-leading lower leak detection threshold of 0.03 gallons per minute. Operators can rely on SmartBall to check ILI callouts for pinhole leaks. If a defect is leaking, operators can take swift action knowing the exact leak location and magnitude.

Ongoing threat monitoring with SmartBall ensures the pipeline is contained and that the defect has not grown to the point of leaking. Threat monitoring is quickly becoming a preferred solution for operators to surveil degrading pipeline conditions, especially in high consequence areas.

Threat monitoring enables operators to manage risk while giving them more time to make million-dollar repair decisions.

Threat monitoring empowers timely repair planning and prioritization. It gives operators more time to identify a favorable repair window or plan complex repairs in sensitive or remote locations. By taking this approach, operators can achieve the cost and resource efficiencies of a highly planned repair versus an emergency intervention.

When there is doubt over the need to dig, SmartBall can monitor the area in question until a decision is made. This gives operators more time to determine the extent of degradation and better understand time to failure. In some cases, pipeline owners may discover their infrastructure can continue to operate safely for years to come, resulting in significant savings.

PureHM offers full-service SmartBall inspections, but technology licensing is also available to give operators flexibility to survey the pipeline and threat as frequently as needed.

Threat Monitoring in Action

Earlier this year, a Canadian operator reached out to PureHM after an inline inspection tool identified a crack in their pipeline. The operator was unsure whether the callout was a through-wall defect warranting an immediate repair.

The defect was at a river crossing – increasing the consequences of a failure but also making repairs more challenging.

PureHM partnered with the operator to monitor the area in question with the SmartBall platform. The operator launched the tool, and PureHM retrieved the tool and analyzed the acoustic data. This flexible solution enabled the operator to reduce inspection costs and run the tool on their schedule.

PureHM and the operator routinely monitored the affected segment for five months — ensuring product containment and protecting a high-consequence area. During this time, further investigations into the defect revealed that it was not as severe as previously thought. This ultimately saved the operator millions of dollars in repair costs.

Threat monitoring is a cost-effective way to manage pipeline damage, verify that your pipeline is contained, and gain peace of mind while planning repairs. Reach out to us today to learn more about threat monitoring with Smartball.