Leading the Way

More than a decade of pipeline inspection and monitoring positions Miami-Dade County as a leader in managing aging infrastructure

It was still dark when crews arrived at a manhole in the middle of the Northwest Wellfield on the outskirts of Miami, Florida. Underground, a 96-inch pipeline carries 80 million gallons of well water every day. Raw water flows through the critical pipeline more than eight miles to the Hialeah and Preston Water Treatment Plants.

Crews unfurl a tool called the PipeDiver® that looks a bit like a prehistoric fish. The tool will swim through the pipeline, collecting data on its condition. Miami Dade Water and Sewer Department (WASD) has undertaken these critical pipeline inspections for more than a decade. Their sole purpose is to protect the region’s pipelines by identifying and prioritizing repairs to ensure the continuity of reliable service to WASD’s customers.

WASD is one of the largest utilities in the U.S., serving 2.3 million customers and thousands of visitors. They deliver approximately 300 million gallons of clean, safe drinking water to customers every day. The utility also collects and treats about 300 million gallons of wastewater from across the County on a daily basis.

The Canary in the Mine

WASD operates close to 15,000 miles of water and sewer mains. Most of the County’s critical large-diameter pipelines are made of prestressed concrete cylinder pipe (PCCP). In 2010, two significant PCCP failures occurred only months apart. This quickly brought aging infrastructure challenges to the forefront. WASD was concerned that the failures could signal a systemic problem in their PCCP network.

Miami is a busy metropolitan area with more than 300 miles of large-diameter PCCP pipelines. Many of these pipelines are buried under major roadways, making replacement extremely expensive and disruptive. Replacing just one mile of PCCP can cost upwards of $8 million.

WASD needed a solution to safely maximize the life of their buried infrastructure while implementing a phased and targeted replacement approach.

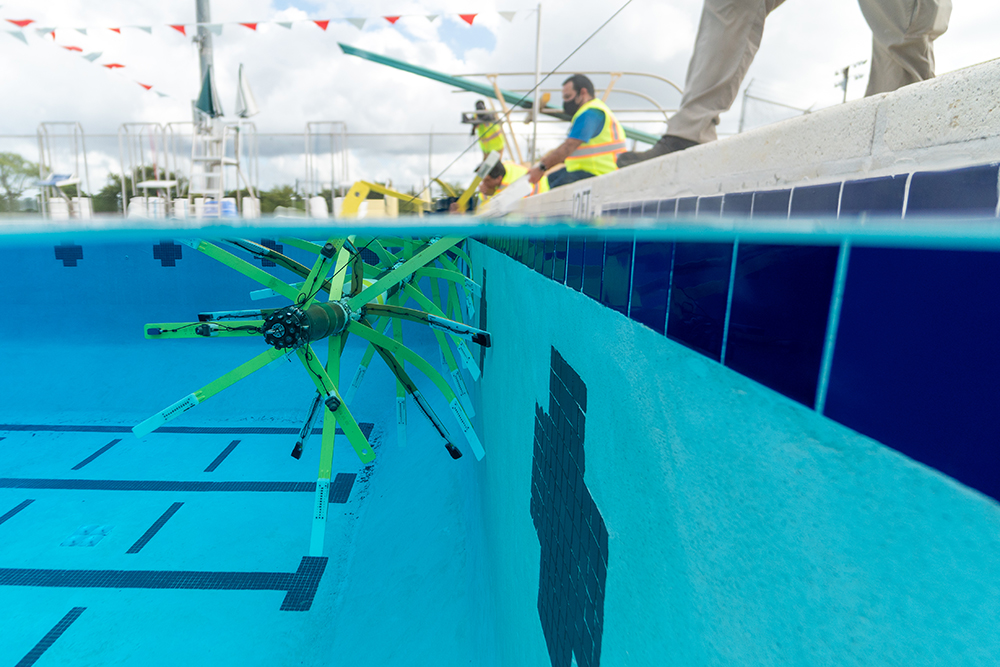

Preparing the PipeDiver to inspect a water transmission main north of downtown Miami

Inspection Informs Action

In 2010, Miami-Dade Water and Sewer Department launched an aggressive pipeline inspection program in partnership with Pure Technologies, a Xylem brand.

Using innovative, inline inspection tools, WASD can assess a pipeline’s condition without taking it out of service. This limits disruption to WASD customers.

Initial inspections focused on the most at-risk pipelines, but over time, the team assessed the remainder of the large-diameter PCCP network. WASD now continuously monitors three high-risk water pipelines and inspects their other pipelines every three to seven years.

Inspecting for leaks is one way WASD protects their pipes. Leaks on large-diameter transmission mains add up. Early leak detection helps the County reduce water loss, protect the region’s water supply — the Biscayne Aquifer — and identify potential pipeline threats.

Pure Technologies’ SmartBall® platform has an acoustic sensor that listens for leaks. The free-swimming tool rolls along the bottom of the pipeline, with the flow of water. It provides data on the location and magnitude of any identified leaks so WASD knows where to dig.

WASD also checks their PCCP mains for pipe wall deterioration using the PipeDiver platform. Like the SmartBall platform, this tool goes with the flow.

Balancing the PipeDiver ahead of an inspection

PCCP’s strength comes from metal wires wrapped tightly around the pipe’s core. When wires break, the pipe weakens. As broken wire wraps increase, so does the likelihood of failure. The PipeDiver tool determines the location and quantity of wire breaks using electromagnetic technology.

Pure Technologies’ SoundPrint® AFO platform monitors three critical water pipelines 24/7. An acoustic fiber optic cable laid inside the pipelines detects wire breaks and relays that information to WASD in near real time. This enables the County to repair or replace a damaged pipe section before it fails.

Inspections identify problem areas so WASD can make planned, proactive repairs. The inspections also identify which pipes are still in good condition. This approach reduces risk and limits unnecessary spending on assets with many years of remaining useful life.

Extracting the PipeDiver at the end of a raw water main inspection

Zero Catastrophic Failures

Since the start of the inspection program in 2010, WASD has achieved their primary goal: preventing another catastrophic pipeline failure.

Today, Miami-Dade is a leader in managing aging buried infrastructure. This program shows how a utility can leverage data to prevent failures, selectively renew their system, and maximize the life of their buried infrastructure.

Miami-Dade’s rich water resources play a major role in the region’s economy, ecology, and culture. By proactively managing their pipelines, WASD is keeping the water flowing now and into the future.

WASD and Pure Technologies crews following a successful pipeline inspection