How to choose the correct speed control for heating systems

The time for single speed or three-speed pumps are over. High efficiency pumps are here. Aside from the higher motor efficiency, all modern pumps contain speed control software to further reduce their power consumption. But which speed control is best for which system? Here you will find a brief overview for fixed speed, proportional pressure control and constant pressure control – where they are applicable, what needs to be observed and what happens if the pump is set incorrectly. Some theoretical background combined with practical hints for the installer, all focused on

radiator systems, floor heating and other common heating systems.

Why are high efficiency pumps speed controlled?

Old style pumps were driven by asynchronous motors. The magnetic field of the stator of these pumps always ran at the grid frequency, while the rotor ran slower because of the slip. High efficiency pumps are driven by synchronous motors with variable frequency. In addition, the high efficiency of these motors makes it possible to detect the actual operating point of a pump with reasonable accuracy. Combine this with the fact that the 32bit microprocessor built into these pumps has a lot of spare time and you can understand why it is possible to implement all kinds of speed control scenarios in these pumps.

Fixed speed control

Setting the pump to one single pump curve is the only option in systems with constant hydraulics. Let’s take the charging loop for the domestic hot water tank. The heat exchange coil resistance is constant, and the only signal comes from a thermostat that declares that the hot water in the tank is getting lukewarm. The boiler starts and kicks on the pump in the loop. There are two important things to remember here. The first is that this pump will only run maybe an hour a day, or two if there are teenage daughters in the house. The second is that we cannot look at the pump individually, but we always need to consider total system efficiency.

For that reason, the pump should be set at a level high enough to prevent the boiler from starting to cycle before the thermostat signals a fully heated tank. A cycling boiler is far worse for system efficiency than a pump set a few watts too high. Add into that the fact that a lot of boilers will give priority to the recharging loop and that your house may not get heat during this time, and you have one more reason to err on the side of caution, i.e., on the high side.

Another example of constant hydraulics is a solar system; there is a potential problem lurking here: if you replace an old circulator with a high efficiency (HE) one, remember that a lot of the old solar controllers manage speed control by cycling power on and off several times a second. This won’t work for an HE pump. In fact, it will destroy it rather quickly. Change the controller setting to “constant speed” and then set the pump speed such that you are sure to avoid overheating in the solar panels until you can source a compatible controller.

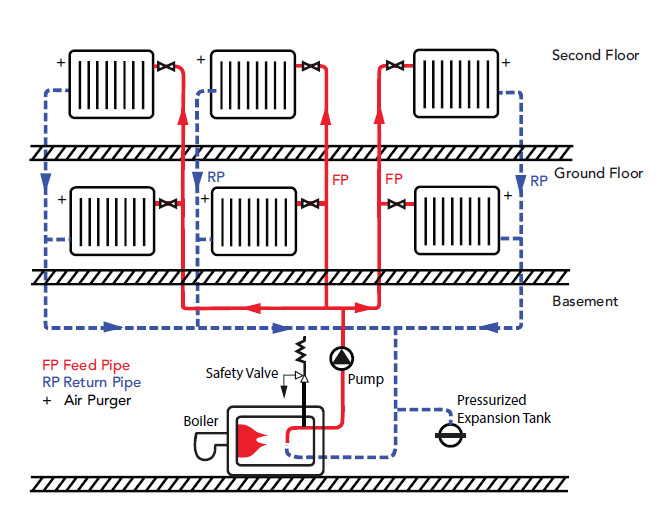

Radiator heating loop

This is the most common hydronic heating system. A boiler provides the heat, a set of distribution pipes runs through the whole house and the radiators branch off of the feed pipe and return cooler water to the return pipe. To make the system efficient, the radiators are equipped with thermostatic valves. These valves are the reason for the wide variability of the hydraulic resistance in such a system. Simply put, on a nice afternoon in March, with spring in the air, only some rooms on the Northern side of the house may have open thermostatic valves while the vast majority of the house is warm enough. The system resistance will be very high and the required flow of water low. On a cold December morning however, you have the opposite: all rooms are calling for heat, the valves are open and the system resistance is extremely low while a lot of flow is required.

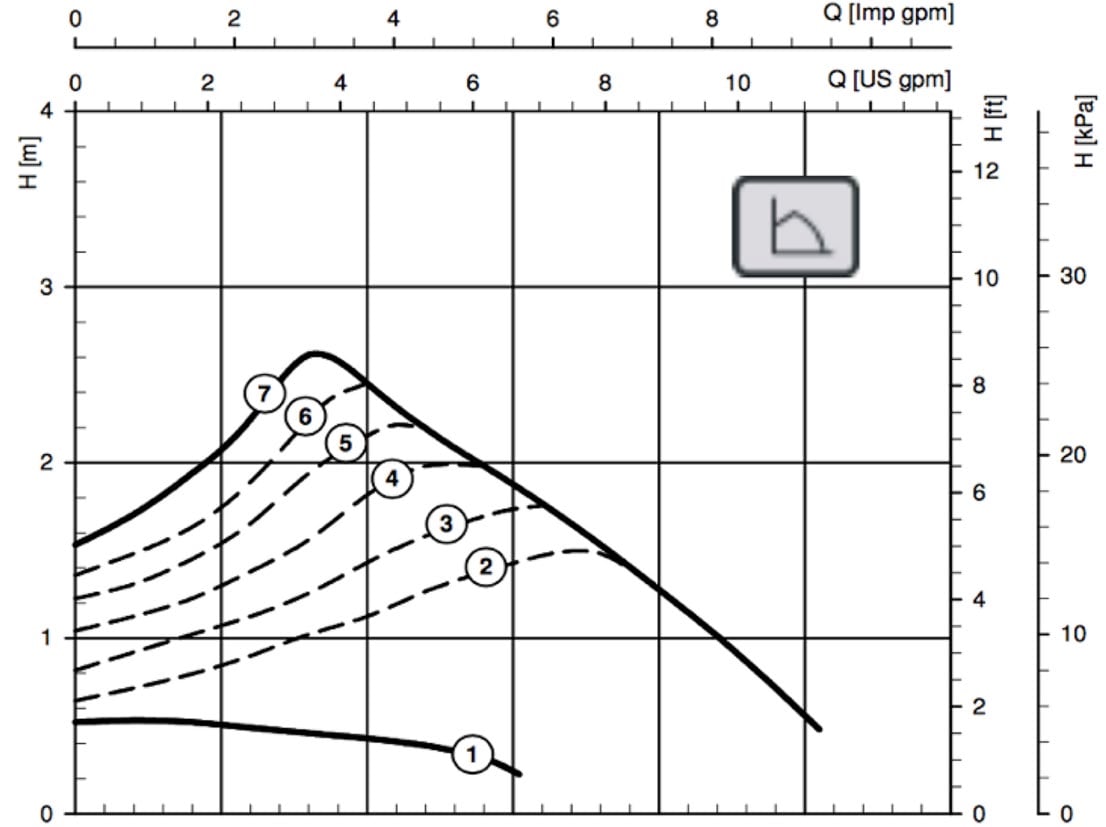

To serve such systems best, the industry has come up with a control scheme called proportional pressure control. It starts with the assumption that about half of your pressure loss in the system will be in the distribution pipe while the other half is lost in the radiators. Consequently, the pump is controlled such that it will respond to a decrease in flow with a reduction of its head and that at zero flow, when all valves are closed, it will provide half the head pressure it has at maximum flow.

So how do you set such a pump? The pump needs to be strong enough to provide heat for the whole house, and therefore you should set it to reach maximum head when all valves are open. If you know your maximum design flow, you can pick that point out of the pump diagram. If not, you open all the thermostats in the house fully (assuming hydraulic balancing has been done), and then increase the power setting slowly until you see that the head pressure is not increasing anymore.

What happens if your setting is off? On the low side, you may experience boiler cycling and insufficient heating. On the high side, you may get “whistling” thermostatic valves. Whistling is surely inconvenient, but cycling means less efficiency – so, if you err, do it on the high side.

Limits of proportional pressure control

Since a Delta-Pv pump reacts to changing hydraulics only, there are cases where it has its limitations. The most obvious one is during nighttime setback. Your boiler reduces the feed temperature according to its timer setting to let the house cool down at night. All thermostatic valves react immediately and open fully, since they sense that the rooms are too cold. And the pump revs up to its maximum setting despite the fact that there is really no need for all that flow.

Several manufacturers have added nighttime setback detection by monitoring the water temperature flowing through the pump. They let the pump go to minimum speed whenever the temperature of the heating water drops quickly, and the pump comes back to normal when the water temperature increases quickly. The problem is that the pump does not know the outside temperature, and while the minimum pump performance may be sufficient most of the time, there can be very cold nights where the radiator furthest from the boiler may not get enough flow and may freeze up. For that reason, the nighttime setback feature can be disabled.

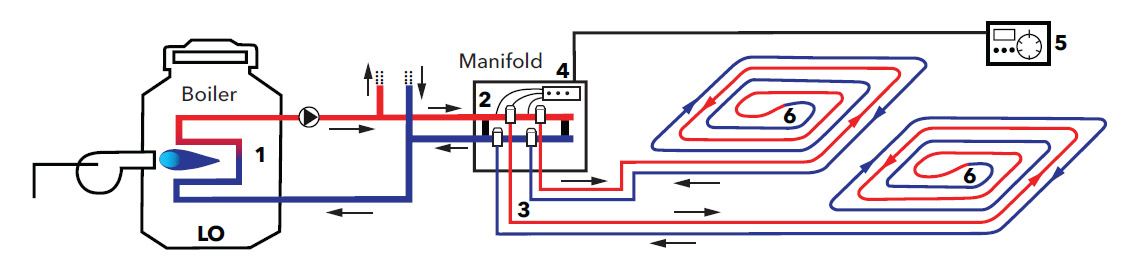

Constant pressure control

Constant pressure control is ideal for systems in which the distribution pipe is non-existent or very short. A prime example is underfloor heating. The distribution pipe consists in most cases of an extremely short pipe run and the manifold. In such cases, system resistance is negligible. Therefore, the pump should supply the individual loops of the underfloor heating system with the same head pressure regardless of how many rooms are being heated.

The setting of such a pump is comparatively easy. The underfloor heating manufacturer will have specified the correct differential pressure for the individual loops, and the pump just needs to be set to this value. If necessary, adjustments can be made to counter noise or insufficient heating.

System efficiency versus pump efficiency

A high efficiency pump in a single family house will consume in the order of 50 to 100 kWh of energy a year. To heat the house, typically more than 100 times that energy is required. Even if we account for the fact that electrical energy is more precious than heat, it should be clear that the overriding concern should always be to maximize the efficiency of the total system. If you can lower the maximum feed temperature a bit by decreasing the delta-t in the loop through a higher pump setting, the heating energy saved in most cases will greatly exceed the additional pump consumption.

A word of caution: While homeowners usually complain once a year about their gas bill, modern pumps with their nice displays and buttons make it very tempting for them to start saving in the wrong place. If you have adjusted their heating system correctly, it may be a good idea to put a sticker on the pump showing the correct settings.

Outlook

Finally, you should consider the limits of autonomous pump control. Pumps nowadays have intelligence built into them but they are seriously lacking in sensory input. They can detect the system resistance and, if they have a built-in temperature sensor, they can detect system temperature. Period. On the other hand, your heat source has comparatively a wealth of input, ranging from outside temperature information to that little button on your home heating control that informs it that you are having a party and that therefore you do not want the house to cool down at 10 p.m. The additional information makes it much easier for the control of your boiler or heat pump to optimize overall system efficiency. In a time where even our refrigerators are getting a web connection, you can expect that before too long even standalone pumps will have a wireless connection to their boilers and will follow higher orders.