![]()

SPEND LESS ON ENERGY

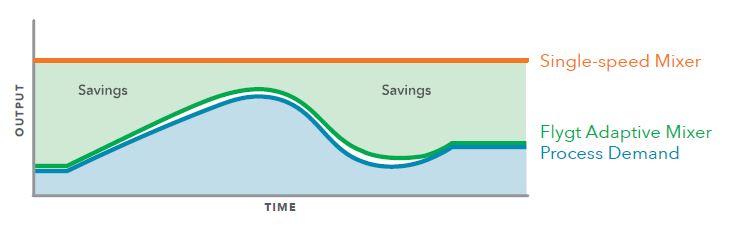

Flygt Adaptive Mixers can be controlled or automated to deliver only the thrust required — and nothing more — which results in remarkable energy cost savings.

![]()

IMPROVE PROCESS RESILIENCY

Sediment on your tank floor? Seasonal fluctuations? Process upgrades? Flygt Adaptive Mixers let you adjust output , manually or automatically, to achieve the required mixing process result — no matter what.

![]()

INCREASE MIXER UPTIME

With comprehensive monitoring, auto-correction functions, and a sealed, protected environment for the drive, Flygt Adaptive Mixers represent a new level in mixing reliability.

![]()

REDUCE MIXER INVENTORY

Because the same adaptive mixer model can be used for different applications across your plant, your investment in spare parts and backup mixers can be reduced.

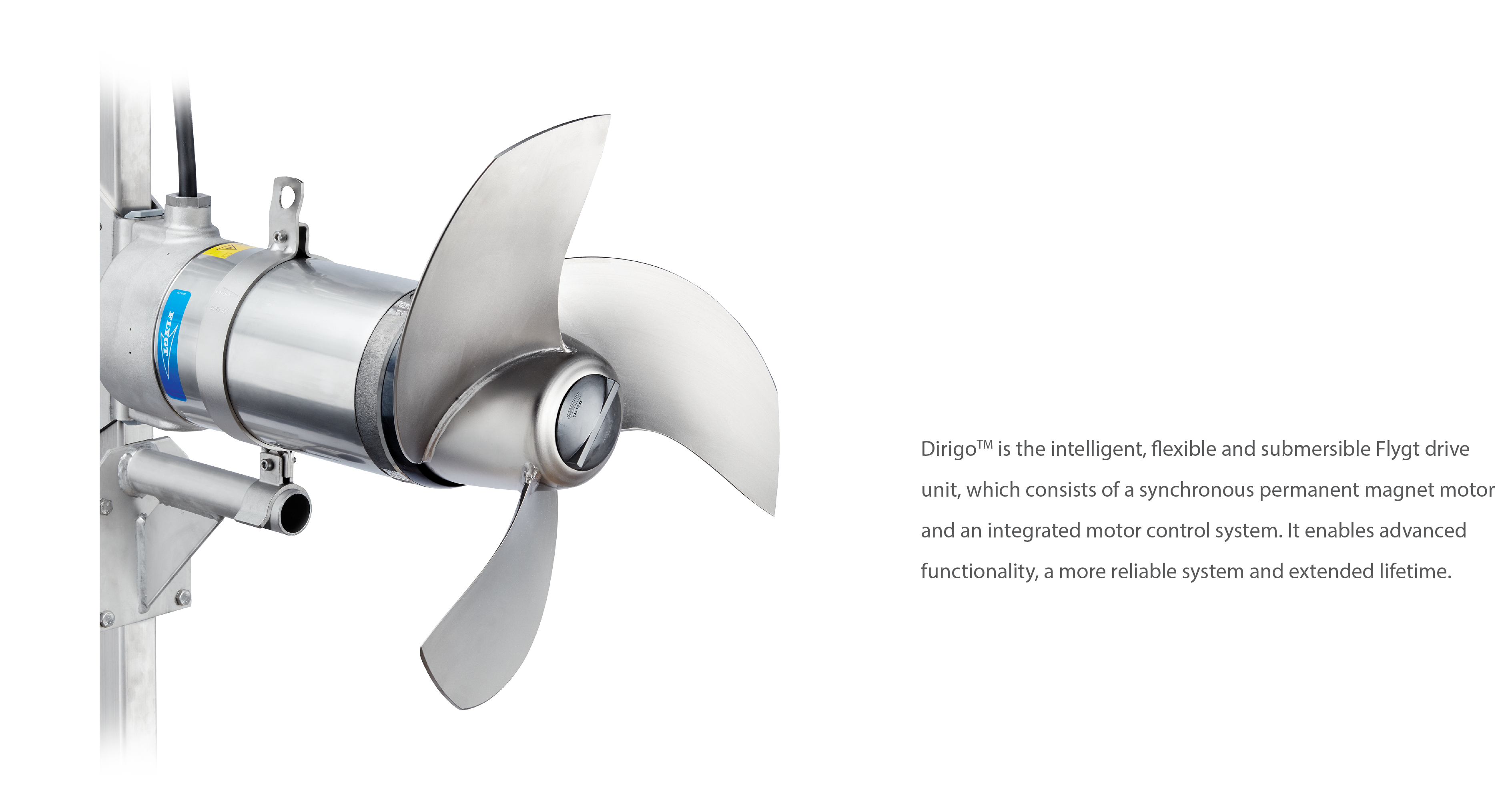

Outstanding efficiency with IE4 equivalent motor

Synchronous permanent magnet motors are super premium according to international standards. When compared to lower classifications such as IE3 — often based on conventional asynchronous technology — motors with IE4 efficiency use less energy.

Enhanced drive system reliability

The integrated control electronics of Flygt Adaptive Mixers are sealed inside a dustfree, non-oxidizing environment, reducing the risk for drive failure. Since the mixer is submerged in cooling media, no fan is needed, which otherwise is the most failprone component of a traditional VFD. This integrated design also eliminates potential errors from sizing, set-up, and wiring.

Easy access to integrated control and monitoring functions

Operators can easily control and adjust the output via a tank-side control panel, PLC, or a plant-wide control system. Integrated monitoring functions include power consumption, energy meter, running time, drive temperature, phase loss alarm, and overload alerts.

Automated mixer control

Flygt Adaptive Mixers can be fully automated to adjust output to real airflow conditions, based on data from an airflow sensor or from a built-in feature that senses the airflow resistance in the tank. This system variant includes a controller that can also be used to operate multiple mixers.

Instant adjustment at your fingertips

For infrequent events like seasonal fluctuations, tank cleanings, or plant upgrades, the user-friendly operator panel, or the connected control room, puts you in complete control to adapt your mixer’s output quickly and efficiently.

Process flexibility with automated mixer control

Configuring your mixer for full automation allows for continuous and exact regulation of mixer output to optimize process results, also generating additional energy savings. Different functions are available to enable this automatic output regulation. One of them, for oxidation ditch control, uses a unique, built-in capability to measure real-time airflow resistance in the tank and adjust output automatically and continuously to match actual demand.

Spend Less on Energy

Designed to deliver the exact output you need.

Match output to demand

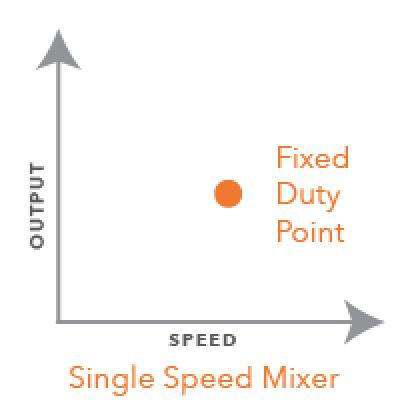

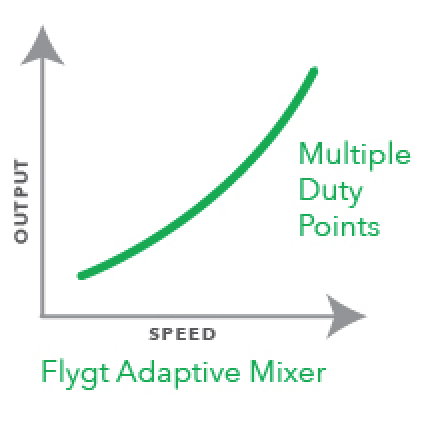

Unlike single-speed mixers, which operate at a fixed duty point and use the same amount of energy regardless of process demands, Flygt Adaptive Mixers only use the energy you need based on an exact set of process demands.

Market-leading ISO 21630 efficiency

With efficiencies of up to 1,700 newtons of thrust per kilowatt of input electrical power, Flygt Adaptive Mixers can reduce power consumption by up to 50%, resulting in significant cost savings compared to a conventional single-speed mixer.

Proven non-stop performance makes your job easier.

Enhanced drive system reliability

Placing the control electronics inside a dust-free, non-oxidizing environment reduces the risk for drive failure. In addition, the mixer’s integrated components are submerged in a cooling media, which eliminates the need for a fan — the most fail-prone component of a traditional VFD (variable frequency drive). This integrated design also eliminates potential errors from sizing, setup, and wiring.

Integrated monitoring

With a Flygt Adaptive Mixer, you know exactly what is going on without having to touch the mixer — or even leave your control room. Integrated monitoring functions include power consumption, energy meter, running time, drive temperature, phase loss alarm, and overload alerts.

Adjusts for overload conditions

When overload conditions are imminent, a Flygt Adaptive Mixer automatically senses the danger, adjusts output accordingly, and triggers an alarm.

Easy replacement of existing mixers

Flygt Adaptive Mixers can often be installed without changing the existing installation system because they fit most common guide bar dimensions.

Low maintenance costs

From the reduced wear of the mixers themselves — thanks to their variable output — to their advanced motors, ActiveSeal™ technology, and durable hydraulics, Flygt Adaptive Mixers were designed to handle the harsh demands of wastewater treatment with long maintenance intervals.

Lower investment. Flexibility for the future.

Smaller inventory of mixers and parts

Because Flygt Adaptive Mixers cover a range of duty points, plants can deploy them across different tanks and applications, which requires a smaller capital investment in spare parts and backup mixers

A single-speed mixer has a fixed output that does not allow for change, even if the process demand were to increase or decrease.

Conventional: One fixed output per mixer. Various brands and models over time.

Lower investment upon reuse

With their easy adjustment, Flygt Adaptive Mixers can be reused in other tanks and applications. During a process redesign or upgrade, Flygt Adaptive Mixers can even be exchanged among different plants — avoiding the need to rebuild

A Flygt Adaptive Mixer has an output range for the utmost in flexibility in response to process changes.

Flygt Adaptive Mixer: One single model with wide output range.