2017 marked the 70th anniversary of the world’s first submersible Flygt pump. Xylem takes a look back at how submersible pump technology has advanced over the years, and at what we can expect in the future. In 2016, Xylem launched the world’s first wastewater pumping system with integrated intelligence. Learn how that technology will be taken further.

How do we create innovative products? At some point, every company in every industry faces this question. This was the case for our design engineers already in 1940, when the first Flygt pumps were produced. Xylem’s long and successful history of innovation is no doubt due to the technical expertise of our developers. However, no successful innovation can be created without one key element: knowledge about our customer’s pain points and critical processes.

It is precisely this knowledge that motivated engineer Sixten Englesson, based in Emmaboda, Sweden, to begin researching how to use a submerged pump for dewatering. Working for Flygt pumps as a design engineer since the early 1940s, he knew that our customers in the building sector needed this type of technology. This knowledge motivated him to work on his solution and develop a prototype in 1946.

One year later, in 1947, Englesson released a prototype for the world’s first-ever submersible dewatering pump. This innovation would transform entire industries, making the working lives of millions of people easier and helping companies work smarter and more efficiently.

How much has submersible pumping changed?

For over 70 years, Xylem’s Flygt brand has continuously improved submersible wastewater pumping and mixing. At each step of the way, Xylem engineers have asked, what problems do our customers need to solve? Over the years, the company has proven that innovation is part of its DNA. It has introduced state-of-the-art technologies like non-clog impellers, smart controls, and pumping stations designed to work more efficiently.

Then in 2016, Xylem made history again when it released the world’s first wastewater pumping system with integrated intelligence. Xylem’s Flygt brand has always focused on developing technology that helps communities work smarter, more sustainably and efficiently, and in safer environments. Here are some of the stories that have made Xylem who we are.

What the world did with a new kind of pump

In a black-and-white photo from 1947, Sixten Englesson stands in a dark suit with one hand in his pocket and the other holding the frame of his famous “Parrot Cage”, the prototype of the first submersible dewatering pump. Looking at the photo, you wouldn’t be able to guess what the pump could achieve. The submersible pump drained canals in Canada, pumped gold in Africa, and helped raise a 330-year-old warship from the bottom of the sea in Sweden.

What was so different about Englesson’s pump? Before it was invented, anyone who needed to pump water out of a mine or dewater a construction site had to use a pump on the surface. This involved a lot of hoses and platforms that had to be continuously moved. Pumps frequently burned out or were flooded. Many pumps also had their motors in a separate housing, which took up more space.

Although submersible pumps for clean water had been available since the 1920s, they couldn’t handle tougher conditions. Englesson’s innovation to the submersible pump was protecting its motor with two mechanical flat seals. He also modified the pump so that its motor was cooled by the pumped medium. With these modifications, the Flygt B-pump was released to the market in 1948, and orders were soon coming in from around the world.

Everyone wanted wastewater pumping to be easier

The success of the Flygt B-pump led Englesson to start working on a submersible pump for wastewater. If dewatering was a challenge, transporting wastewater was even more challenging since the media is unpredictable. But Englesson had a few ideas that would transform another industry.

Almost a decade later, in 1956, the Flygt C-pump was launched with a number of features that saved time, space and money. It was the world’s first-ever submersible wastewater pump. In order to accommodate wastewater, the pump needed a bigger throughlet, but the main innovation was its self-locking connection. Workers only needed to lower the pump down and it connected itself. Since the motor was integrated into the pump, pumping stations could also be much smaller. These features lowered the overall investment cost.

An innovative spirit that continued to grow

Englesson’s curious mind wasn’t limited to pumps, he was also interested in aquaculture and fish farming. When he eventually left the company for other interests, his innovative spirit remained. Over the next several decades, Flygt continued to solve customer challenges through new technology and award-winning innovations.

In 1990s, engineers saw that there was a serious problem that needed solving: clogged pump impellers. Every time a wastewater pump clogged, maintenance crews needed to go out and unclog it, which was expensive and time consuming. Not to mention the problem of overflows and the risk to the environment.

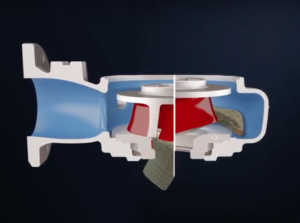

To resolve this problem, in 1997 Flygt introduced the first N- pump. The pump had a clog-free hydraulic design called N-technology, which prevents clogging and reduces unplanned maintenance costs. Then in 2009, engineers enhanced the design by introducing the Adaptive N impeller. This impeller moves upwards to allow larger objects and debris to pass through. With these innovations, Xylem customers can today expect clog-free, high-efficiency wastewater pumping.

Making the perfect pump station

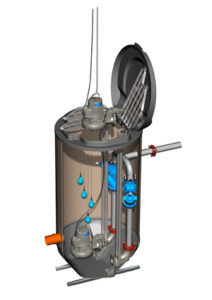

But there was more to be done. For decades, many pump stations were nothing more than flat-bottomed holes in the ground lined with concrete. Xylem’s Flygt engineers began researching how the shape of the pump sump in a station affected the flow of wastewater. They discovered that designing the shape of the bottom of the pump station in exactly the right way would significantly increase efficiency and eliminate cleaning, since this reduced unwanted sedimentation.

In 1997, the Flygt TOP pump station was released: a pre-engineered and packaged pump station solution that delivered superior performance. The design of the station increases turbulence and causes more solids to be removed from the sump. This leaves a minimum of residue beneath the pumps, which is ready to be removed during the next pump cycle. The TOP stations are also easy to install, with a compact design that doesn’t take up much space.

Creating the world’s smartest pump

From Sixten Englesson’s first submersible dewatering pump until today, Xylem engineers have always taken on the toughest challenges to make the work of customers easier. In 2016, they did it again with Flygt Concertor, the world’s first wastewater pumping system with integrated intelligence. This smart system senses the operating conditions of its environment, adapts its performance in real time and provides feedback to pumping station operators.

Flygt Concertor also introduces unprecedented flexibility into pumping systems. It has a performance field with infinite performance curves, and the system is pre-engineered to save time and costs from the moment of installation.

The pumping system also combines built-in sump and pipe cleaning functionalities into a single integrated solution, able to handle floating debris as well as pipe sedimentation. This pump cleaning function, together with Adaptive N-hydraulics, effectively detects and solves clogging from large debris.

Overall, Flygt Concertor simplifies pumping, cleaning and maintenance, while reducing energy use with optimal performance based on real-time conditions. The system is also scalable, which means that operators can add new functionality without losing their initial investment. Since Flygt Concertor can adapt to different conditions, this reduces the variety of pumps needed to cover all applications.

Customers around the world are already benefitting from Flygt Concertor’s innovative features. In a period of approximately six months between 2015 and 2016, a pumping station in the Heathrow Airport Central Sanitation Unit (UK) saved approximately 87 percent of its annual costs in cleaning and servicing. Similarly, a station in St. Tammany Parish (USA) that trialed Concertor, starting in August 2015, saved $1,000 in energy per month due to reduced power consumption during off-peak periods.

The future of submersible pumping systems

As always, Xylem engineers are continuing to ask the question: what problems do our customers need to solve? Looking at global trends of urbanization, increasing energy costs and aging infrastructure, there are a number of pressing challenges. But there are also entirely new solutions.

With the rise of the Internet of Things and big data, cities and companies are connecting device and systems like never before. This brings new opportunities and new challenges. Connectivity can increase efficiency and lower costs, but it also significantly increases the amount of data generated. In the wastewater sector, utilities will need new solutions to connect equipment and systems and to manage and analyze the data they produce.

In 2016, Xylem acquired Sensus, a global leader in smart meters, network technologies and advanced data analytics solutions. Xylem is now working with Sensus to combine smart products and analytics into wastewater systems that will deliver the lowest possible lifecycle costs to customers.

Unplanned maintenance, for example, is one of the key drivers of costs that utilities have for their equipment. But what if unplanned maintenance could be eliminated? In traditional monitoring systems, an alarm is triggered when there is an overflow and a maintenance crew is called out. By collecting and analyzing data, however, the system could use predictive analytics to stop the overflow from ever happening.

Xylem is also investigating innovative new business models for the wastewater, in which all pumps and vital equipment are connected to the cloud. Operators would no longer need to worry about learning and monitoring the exact right setting for each pump. Instead, pumping systems would be monitored remotely, with Xylem specialists using data analytics to ensure optimal performance and preventative maintenance.

All those years ago, Sixten Englesson imagined what problems he could solve if a pump was placed at the bottom of a mine. Today, Xylem imagines the problems it could solve for customers by putting entire pumping systems in the cloud.